Packaging is about more than sealing a product—it’s about protecting your brand, meeting strict safety regulations, and keeping up with customer demand. For many producers, the challenge is clear: how do you scale output, maintain consistent quality, and still stay compliant with evolving standards? That’s where automated food packaging systems come in.

By replacing manual steps with smart, integrated solutions, these systems help food businesses cut labor costs, reduce errors, and minimize downtime. Whether you’re running high-volume protein lines, managing allergen-sensitive SKUs, or looking for ways to shorten changeovers, automation can deliver measurable gains in efficiency and peace of mind.

In this buyer’s guide, we’ll break down what automated systems really include, compare core technologies like thermoformers and tray sealers, and explore how loaders, conveyors, and end-of-line equipment all connect. You’ll also learn how automation supports food safety through clean-in-place (CIP) systems, allergen control, and digital traceability. Most importantly, we’ll show you how to evaluate vendors, model ROI, and future-proof your investment.

Quick Takeaways

- Automated food packaging systems integrate loaders, sealers, conveyors, and inspection tools into a single, high-efficiency line.

- Choosing between thermoformers and tray sealers depends on your SKU mix: thermoformers excel at high-volume runs, while tray sealers win on flexibility and faster changeovers.

- Validated CIP sanitation can cut cleaning times by 30–60%, while allergen control tools like label vision systems reduce recall risks.

- Real throughput is about OEE, downtime, and sanitation windows—not just machine speed.

- Typical ROI falls within 1–3 years when considering labor savings, downtime reduction, and compliance.

- Smart conveyors, predictive maintenance, and digital traceability tools future-proof your packaging line.

- A vendor-neutral scorecard ensures alignment with growth, compliance, and sustainability goals.

Understanding Automated Food Packaging Systems

What Is an Automated Packaging System?

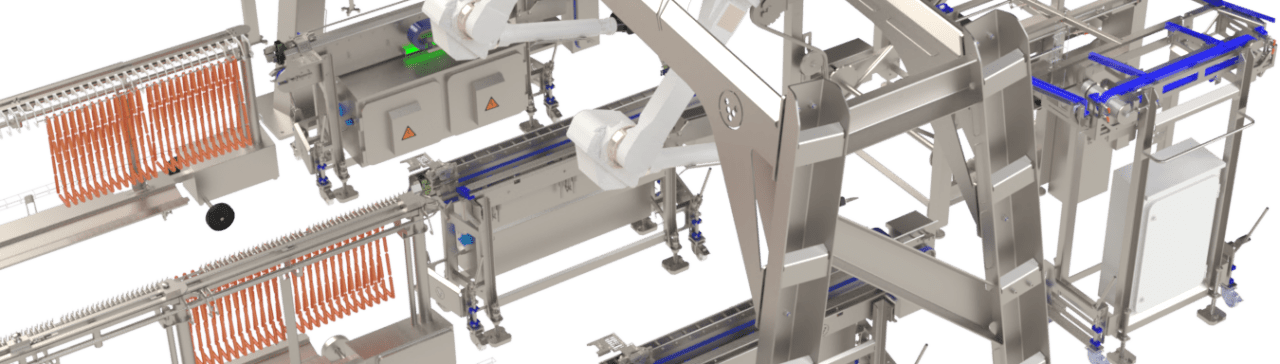

At its core, an automated food packaging system is more than just a single machine—it’s a synchronized line designed to handle product infeed, orientation, sealing, labeling, and palletizing with minimal human intervention. Instead of multiple operators feeding, sealing, and stacking by hand, automation ensures consistency and flow across every step.

These systems typically include:

- Upstream loaders that orient products consistently.

- Primary packaging equipment such as thermoformers or tray sealers.

- Inspection and labeling tools that check accuracy and compliance.

- End-of-line conveyors, case packers, and palletizers that prepare products for shipment.

The result is reduced labor reliance, fewer touchpoints, and more predictable performance.

Why Automation Matters Now

Automation has moved from “nice-to-have” to “essential” for several reasons:

- Labor shortages: Fewer available workers and higher wages make automation more cost-effective.

- Compliance pressures: Regulations like FSMA, GFSI, and EHEDG require traceability and hygiene standards that are difficult to meet manually.

- Customer demand: Retailers push for SKU variety and packaging flexibility, meaning frequent changeovers.

According to Food Industry Executive, automation combined with digitalization improves transparency, waste reduction, and quality assurance—capabilities that are now baseline expectations for competitive producers (Food Industry Executive).

Buyer insight: Think of your packaging system as the “conductor” of an orchestra—every machine is an instrument, but without coordination, the performance falters. Automation ensures your entire packaging line works in harmony.

Packaging Formats and Core Technologies

Thermoformers vs. Tray Sealers

Two of the most common primary packaging technologies are thermoformers and tray sealers:

- Thermoformers: Form cavities directly from rollstock film, fill them with product, and seal. They’re ideal for high-volume, uniform SKUs such as hot dogs, cheese slices, or deli meats. Typical speeds: 80–120 packs per minute. They offer strong seal integrity and efficient use of materials, but require longer changeovers and more tooling.

- Tray Sealers: Use pre-formed trays that are filled and sealed with film. They shine in multi-SKU environments like ready meals or promotional packaging. Typical speeds: 40–80 packs per minute. While slower at peak, they allow for quicker format swaps and greater flexibility with recyclable or compostable trays.

When to choose which:

- If you run long, uniform SKUs, a thermoformer will maximize throughput.

- If your operation handles frequent promotions, seasonal SKUs, or retailer-specific formats, a tray sealer will likely deliver higher net efficiency.

VSP and MAP Applications

Both Vacuum Skin Packaging (VSP) and Modified Atmosphere Packaging (MAP) are widely adopted. VSP enhances shelf appeal with tight-fitting film and extends shelf life, while MAP modifies gas composition to slow spoilage.

Unique insight: Many processors overlook the utilities footprint. Thermoformers generally require more compressed air and cooling, while tray sealers are often lighter on infrastructure—something to factor into your ROI calculations.

Upstream and Downstream Integration

Why Loaders Are Your Hidden Bottleneck

While buyers often focus on sealers, many bottlenecks actually occur before sealing—in product loading and orientation. Misaligned sausages, for example, can cause jams or poor seals. Velec’s sausage loaders evolved from manual trays to fully automated curved and mechanical loaders that align products gently and consistently. This directly impacts OEE by reducing short stops and changeover delays.

Conveyors and End-of-Line Systems

Conveyors may seem mundane, but they define system balance. Smart conveyors equipped with sensors, SCADA connectivity, and predictive maintenance keep flow steady, reduce unplanned downtime, and improve traceability.

According to Velec’s Conveyor Design for Food Packaging, conveyors should be viewed as profit centers, not just transport tools, since poor conveyor design leads to costly line stoppages.

Buyer insight: Ask vendors to provide “end-to-end” OEE modeling that includes loaders and conveyors—not just the nameplate speed of the sealer. This reveals the true throughput potential of your line.

Hygiene, Safety, and Allergen Control

Clean-in-Place (CIP) as a Game Changer

Manual sanitation is time-consuming and inconsistent. With CIP-enabled automated food packaging systems, validated cleaning cycles can reduce sanitation time by 30–60%, while ensuring consistent results. Audit-ready logs make compliance straightforward.

Allergen Control Systems

Allergen recalls are among the most common—and most expensive—recall categories. Automated systems help by:

- Vision verification of labels to prevent mislabeling.

- CIP cleaning that removes allergen residues between runs.

- ERP integration that links batch data and traceability.

Hygienic Design Standards

To comply with global standards like EN 1672-2, ISO 14159, and 3-A Sanitary Standards, systems must feature open-frame construction, self-draining surfaces, and tool-less cleaning.

As Velec notes in Avoid Recalls: Allergen Control in Automated Packaging, these features aren’t optional—they’re strategic safeguards against brand damage.

Hygiene isn’t just about compliance—it’s a brand differentiator. Retailers and food service companies increasingly ask suppliers to demonstrate validated cleaning protocols before approving new vendors.

Controls, Data, and Digital Layer

Recipe-Based Configuration

Modern systems automate dozens of variables—temperature, vacuum, dwell time, conveyor pitch, label content—based on stored “recipes.” This reduces operator error and enables fast changeovers.

Diagnostics and Predictive Maintenance

Sensors embedded in conveyors and sealers monitor motor loads, seal dwell, and vacuum draw. These diagnostics feed into predictive maintenance models that reduce unplanned downtime—a major ROI driver.

Traceability and Audit Readiness

Systems like MyVelec export digital sanitation logs, recipe changes, and maintenance records. This supports both FSMA preventive controls and GFSI audits by proving compliance with hard data, not just verbal assurances.

Quick Tip:Don’t just ask vendors for a list of features—ask how their system integrates with your ERP/MES platforms to provide digital diagnostics logs and traceability.

Measuring Real Throughput and ROI

How to Model Capacity Beyond “Nameplate Speed”

A machine’s rated speed doesn’t tell the whole story. True throughput must account for OEE, downtime, and sanitation cycles.

- Thermoformer example: 100 ppm × 80% OEE = 4,800 units/hour → minus 60 minutes/day for CIP = ~3,900/hour.

- Tray sealer example: 60 ppm × 85% OEE = 3,060 units/hour → shorter changeovers keep net output competitive.

ROI Levers That Matter

- Labor redeployment: Less reliance on manual loaders.

- Downtime reduction: Faster CIP and changeovers.

- Scrap reduction: Better seal consistency and label accuracy.

- Compliance savings: Lower risk of recalls and audit failures.

Most Velec customers achieve ROI within 1–3 years—a finding echoed in PMMI research showing productivity is the top driver for automation adoption (Food Logistics).

Risk Management and Compliance

Preventing Recalls

Mislabeling and allergen cross-contact remain top recall causes. Automated food packaging systems mitigate these risks with integrated label verification, allergen cleaning protocols, and ERP-linked traceability.

Regulatory Mapping

- FSMA preventive controls: Allergen control and sanitation.

- GFSI: Global audit certification.

- EHEDG/USDA: Hygienic equipment design.

Keyence notes that sensors and automation enhance defect detection and traceability—capabilities vital for compliance (Keyence).

Unique insight: Instead of viewing compliance as a cost center, position it as a sales enabler. Retailers increasingly demand compliance documentation during supplier qualification—automation helps you win shelf space.

Sustainability in Automated Packaging

Packaging automation plays a central role in sustainability:

- Material efficiency: Thermoformers reduce waste by forming packages from rollstock.

- Flexible material use: Tray sealers quickly adapt to rPET, paperboard, or compostable trays.

- Energy efficiency: Modern machines integrate energy recovery and efficient drives.

Velec’s Thermoformers in Reducing Environmental Impact highlights how automation reduces film scrap and supports recyclable substrates.

Sustainability isn’t just about packaging material—it’s about system design. Faster changeovers reduce product waste, which has a larger carbon footprint than packaging itself.

Real-World Scenarios

High-Volume Protein Producer

A national hot dog processor chose a thermoformer with mechanical loaders and CIP systems. Result: faster throughput, fewer recalls, ROI in under 2 years.

Ready Meals Manufacturer

A mid-size ready meal company adopted a tray sealer line with recipe-based controls. Frequent SKU changes didn’t disrupt throughput, ensuring agility in promotions.

Premium Brand with Retail Scrutiny

A premium protein brand invested in MAP/VSP systems with vision-based label verification. This ensured compliance with retailer audits and reduced returns.

Future-Proofing Your Investment

Trends to Watch

- Robotics and cobots: Expanding role in loading and palletizing.

- AI-driven predictive maintenance: Reduces downtime.

- Cloud-based monitoring: Remote diagnostics and performance visibility.

Scalability and Modularity

Small producers can adopt scalable automated food packaging systems—starting with tray sealers or simple conveyors, then expanding to integrated lines.

Velec’s Scaling Up for Small Businesses emphasizes modular automation as a pathway to growth.

Future-proofing isn’t just about technology—it’s about training. Investing in workforce upskilling ensures operators maximize system potential and reduces resistance to adoption.

Conclusion

Investing in automated food packaging systems is about more than efficiency—it’s about protecting your brand, meeting regulatory requirements, and positioning for long-term growth.

The right system integrates loaders, sealers, conveyors, and controls into a seamless process. As we’ve seen, thermoformers excel in long, high-volume runs, while tray sealers win on flexibility. Loaders and conveyors determine your true throughput, while CIP and allergen control keep your line audit-ready. With digital diagnostics and recipe-based controls, your system becomes both smarter and more compliant.

The payoff is real: most businesses achieve ROI within 1–3 years by cutting downtime, reducing labor dependence, and avoiding costly recalls. More importantly, automation enables you to meet retailer demands, reduce environmental impact, and adapt to tomorrow’s market.

What does an automated food packaging system include?

An automated food packaging system typically includes product loaders, conveyors, sealing machines (like tray sealers or thermoformers), inspection tools, labeling systems, and palletizers—all working together to streamline packaging from start to finish.

Should I choose a tray sealer or a thermoformer?

Choose a thermoformer if you run high-volume, uniform products—it offers faster speeds. Tray sealers are better for flexibility, frequent changeovers, and packaging multiple SKUs like ready meals.

How does Clean-in-Place (CIP) improve food packaging systems?

CIP systems automate sanitation, cutting cleaning time by 30–60%. They also generate audit-ready logs, helping you meet food safety standards with less downtime.

Can automation help manage allergens in food packaging?

Yes. Automated systems support allergen control through CIP cleaning, label verification with vision systems, and ERP-based traceability to reduce cross-contact and recall risks.

What is the return on investment (ROI) for automated food packaging?

Most food producers see ROI within 1–3 years, thanks to labor savings, reduced downtime, fewer recalls, and improved compliance.

Will automation replace workers in my facility?

No. Automation typically shifts workers to higher-value tasks like quality control, maintenance, and system oversight, rather than eliminating jobs.

What is predictive maintenance in food packaging systems?

Predictive maintenance uses sensors in conveyors and sealers to detect wear or issues early. This helps prevent unplanned downtime and extends equipment life.

Can small food businesses afford automated packaging systems?

Yes. Scalable systems let small producers start with basic automation—like a tray sealer or smart conveyor—and expand as they grow.

References

- Velec Systems. Sausage Loader Evolution: From Manual to Fully Automated Systems.

- Velec Systems. End-of-Line Packaging: Fundamentals of Flow, Flexibility, and Balance.

- Velec Systems. Conveyor Design for Food Packaging: Boost End-of-Line ROI.

- Velec Systems. Avoid Recalls: Allergen Control in Automated Packaging.

- Velec Systems. Scaling Up: How Small Food Businesses Can Benefit from Packaging Automation.

- Velec Systems. How CIP Systems Reduce Downtime and Improve Food Safety.

- P Market Research. Industrial Automation in Food and Beverage Market. pmarketresearch.com

- Keyence. 6 Benefits of Food Packaging Automation for Quality Control. keyence.com

- Food Industry Executive. The 4 Perks of Implementing Digitalization and Automation in the Food Packaging Industry. foodindustryexecutive.com

- PMMI / Food Logistics. How Ongoing Automation and Robotics Revolution Transforms Packaging. foodlogistics.com