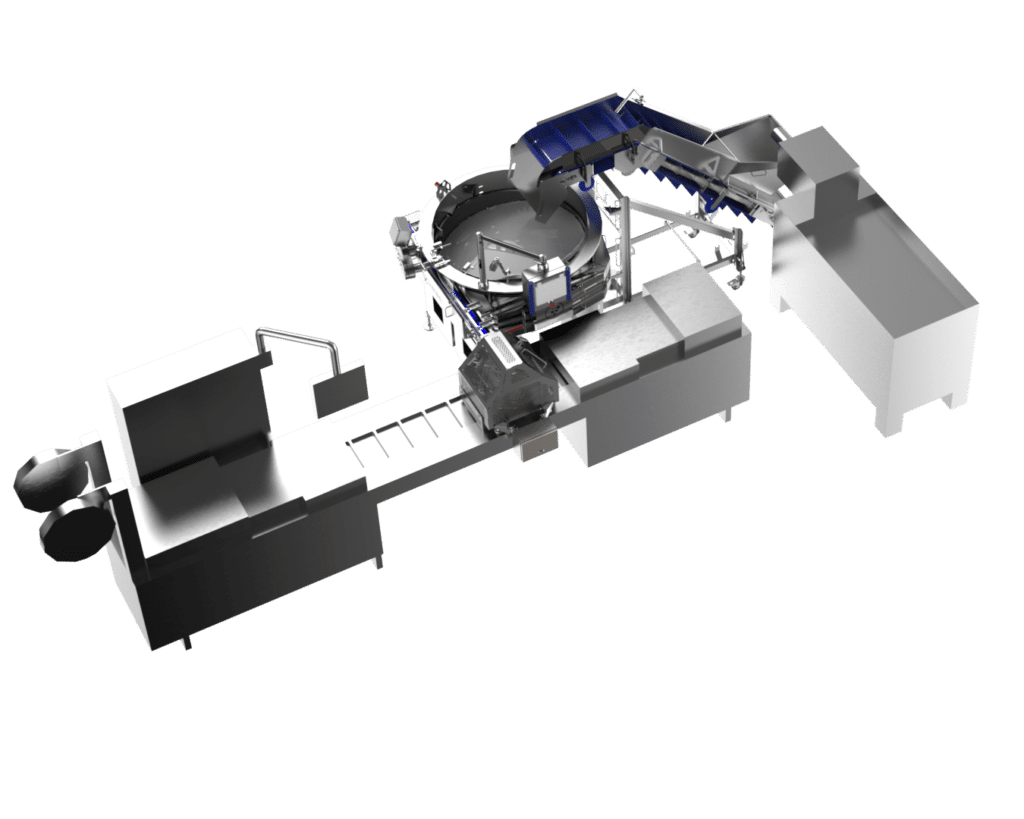

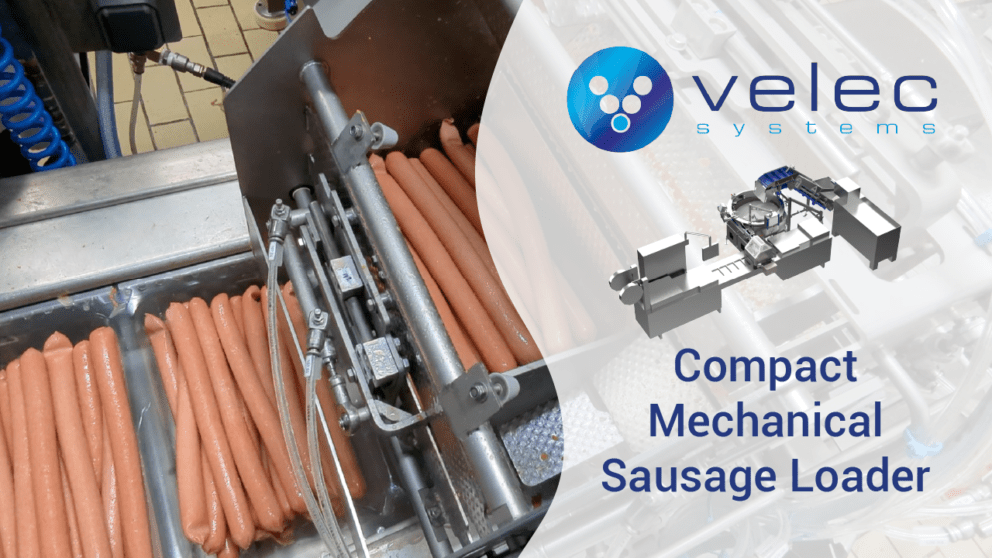

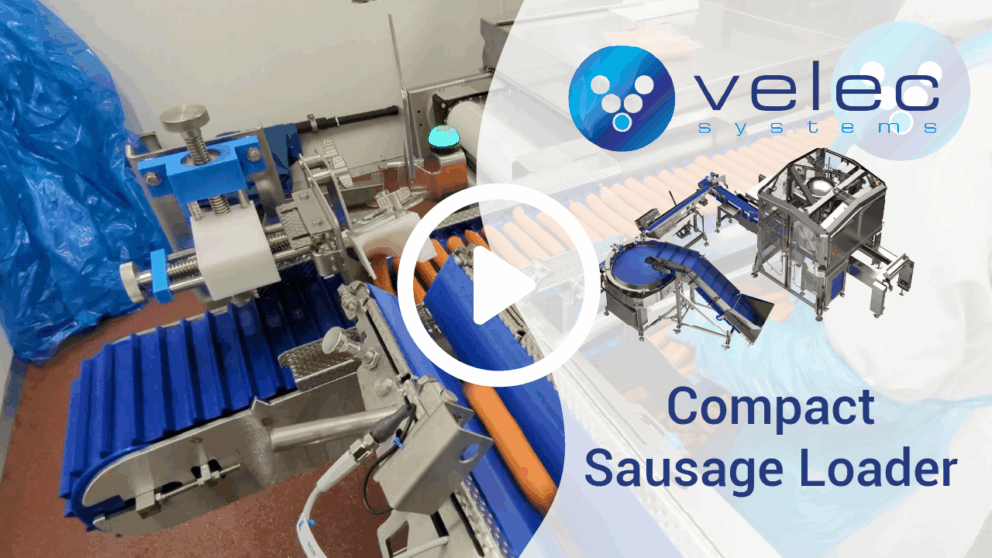

Affordable, extremely compact and hygienic, our Mechanical Sausage Loading offers you various advantages to help you increase your OEE.

- It easily fits in your existing line

- Ensure the food safety of your products before their primary packing

- It adapts to your products

- User-friendly, it facilitates your operations

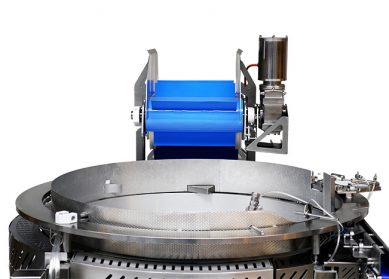

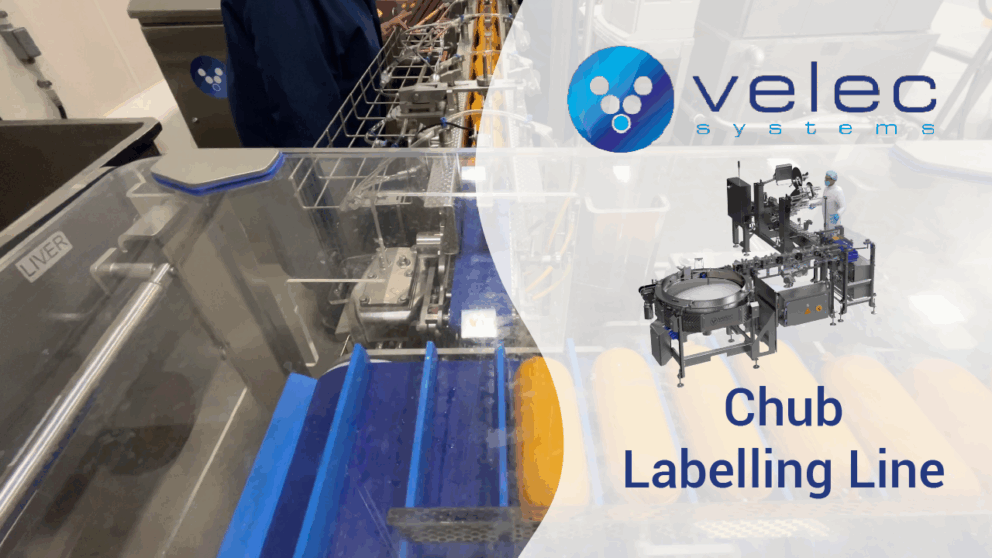

Because sausage manufacturers typically process a wide range of recipes with different casings, lengths, weights and diameters, our solution is highly versatile.

Capable of loading all types of sausages, and positioning them perpendicular or parallel to the movement of the film in your thermoformer in even or odd numbers, it allows great production flexibility.

Increase Your OEE

| SINGLE LINE | |

|---|---|

| Product Diameter | 21 to 23mm |

| Product Length | 260mm |

| Output | Up to 154 products/min |

| Products/pack | 13, 20 or 25 products/pack |

Gentle Handling of Your Sausages to Maximize your Profits

Today, most sausage loaders available on the market generate a significant quantity of broken sausages, forcing companies to employ additional quality operators.

To avoid this loss of value, we have optimized our lines to ensure your products remain identical to their initial state.

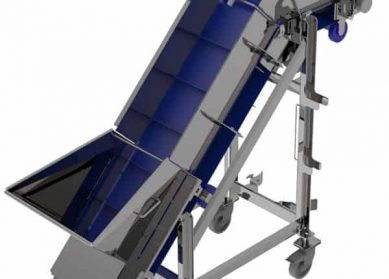

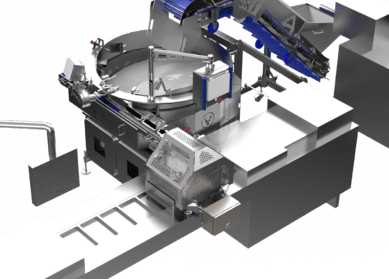

Your sausages are handled on a smooth hygienic belt and gently ordered in the centrifugal machine. Your products are then led towards the double buffer and placed into their main packaging.

The Most User-Friendly and Secured Solution on the Market

Your employees are your most important asset. That’s why we have designed the most user-friendly and safest sausage loader on the market.

For this reason, every part of the machine is at ground level, without stairs or platforms. Operations are reduced to a strict minimum for maximum safety and ease of use for your employees.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).