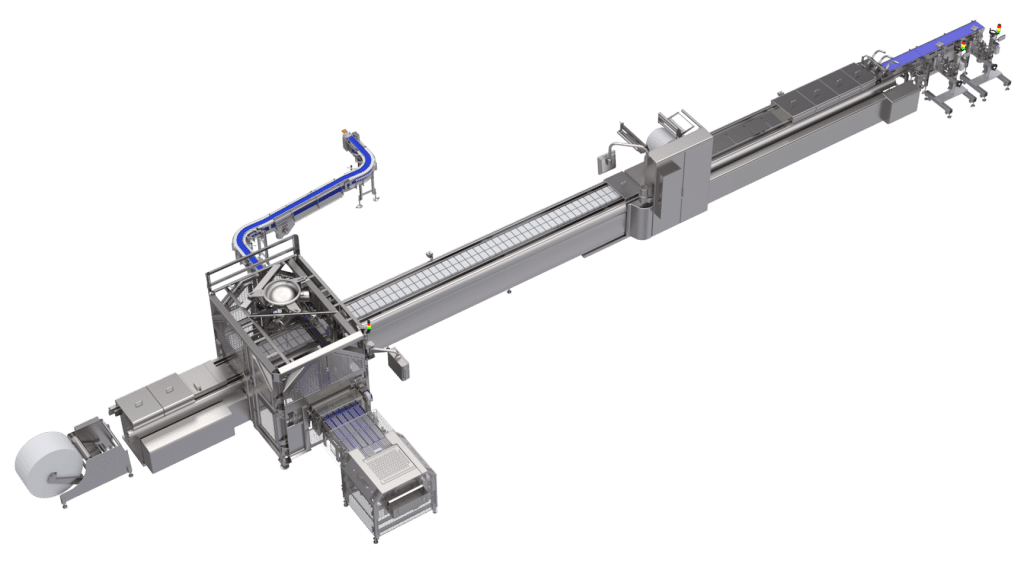

Our Velec Sliced Product Loading system is designed to load your sliced meats into your thermoformer.

Capable of adapting to the dimensions and weight of your products, our solution for loading sliced deli meats counts, loads and packages up to 7,200 products per hour.

Adapt to all your products, whether they are:

- Staggered Stacked

- Stacked Zig-Zag

- Stacked

- Stacked with Interleaves

- Folded

- Chunk

Optimize your Production by Automating Your Process

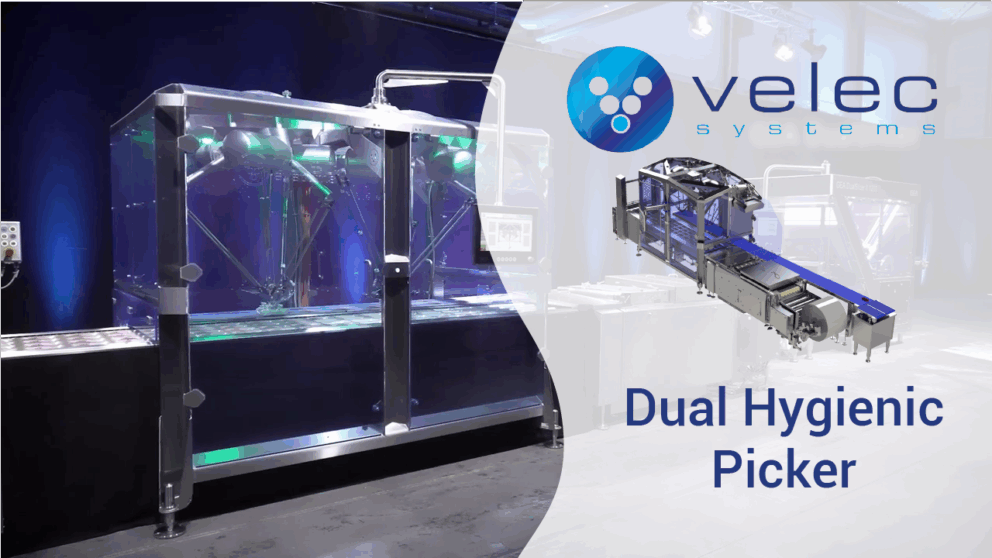

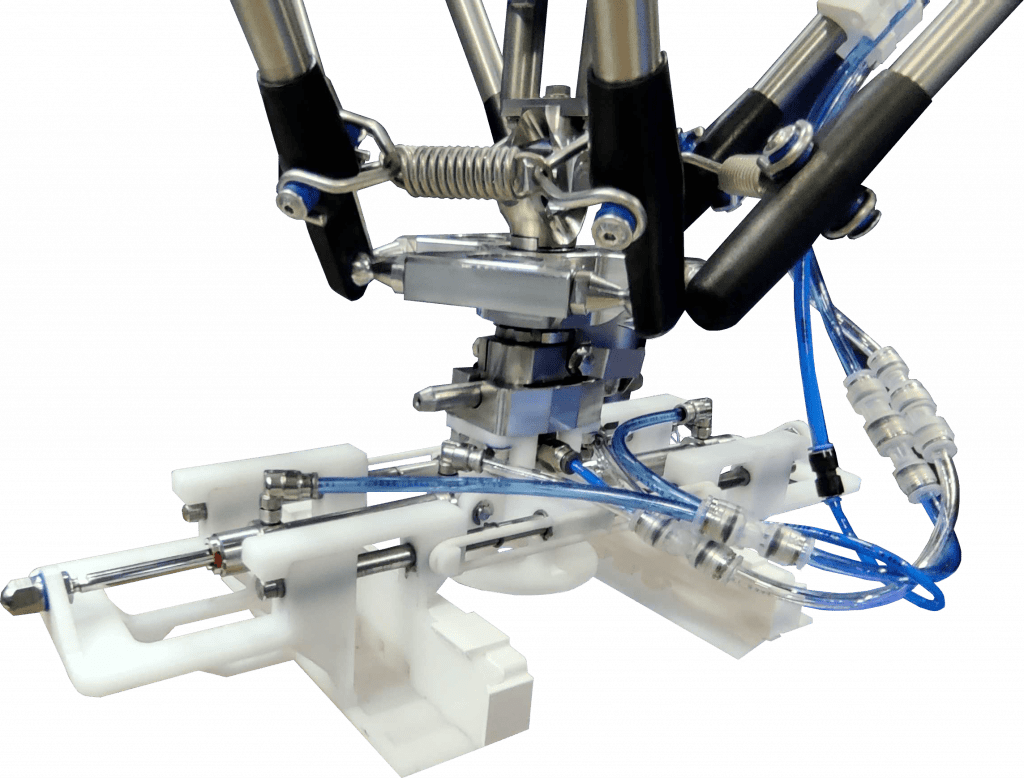

Our automated loading solution increases your production speed, reduces downtime and improves your Overall Equipment Effectiveness (OEE)! Our grippers are designed to quickly and gently pick up your sliced products and place them into your thermoformed pockets.

Moreover, our automated loading solution ensures that each portion of deli meat is consistently and precisely placed into the thermoformer, guaranteeing a consistent quality for each finished product.

By automating the loading process, you reduce manual errors, reducing costs while also reducing your environmental impact.

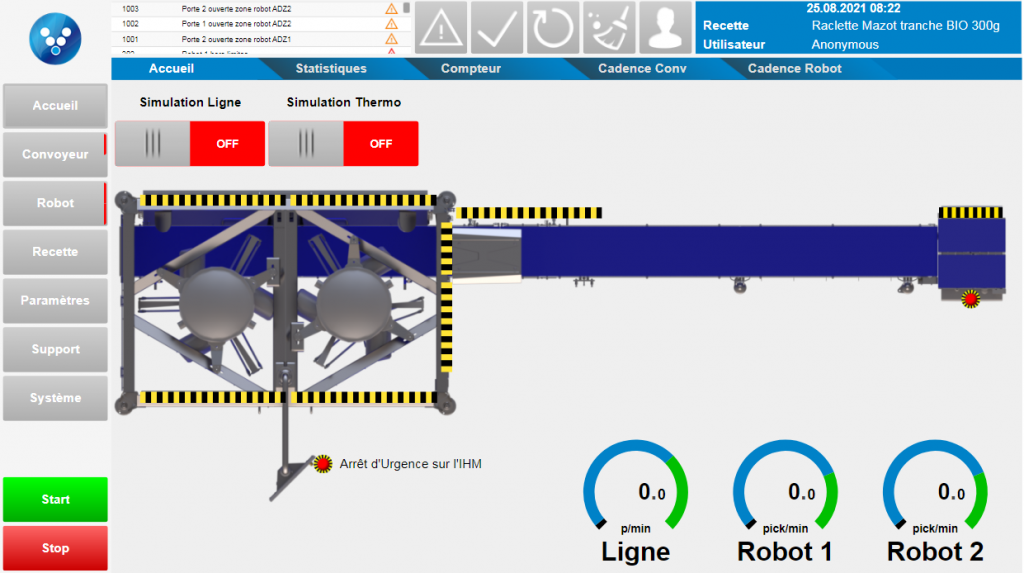

Boost The Efficiency Of Your Production Line With Our User-friendly HMI

To maximize the efficiency of your production line, our experts have designed an easy-to-use automated solution. Thanks to its intuitive HMI, your operators can switch between recipes in the blink of an eye.

To facilitate your cleaning and maintenance operations, our grippers are easily removable without the need for tools. Changing grippers and recipes is made easy with quick adjustments and an unlimited number of recipes.

Benefit From Our Remonte Assistance to Maximize Your Machine Uptime

An interactive assistance is possible thanks to integrated remote access via Ethernet, Wi-Fi or SIM card. The 360° camera control option enables you to establish a direct connection with our experts, who will guide you in restoring your line. You save on travel costs for our teams.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

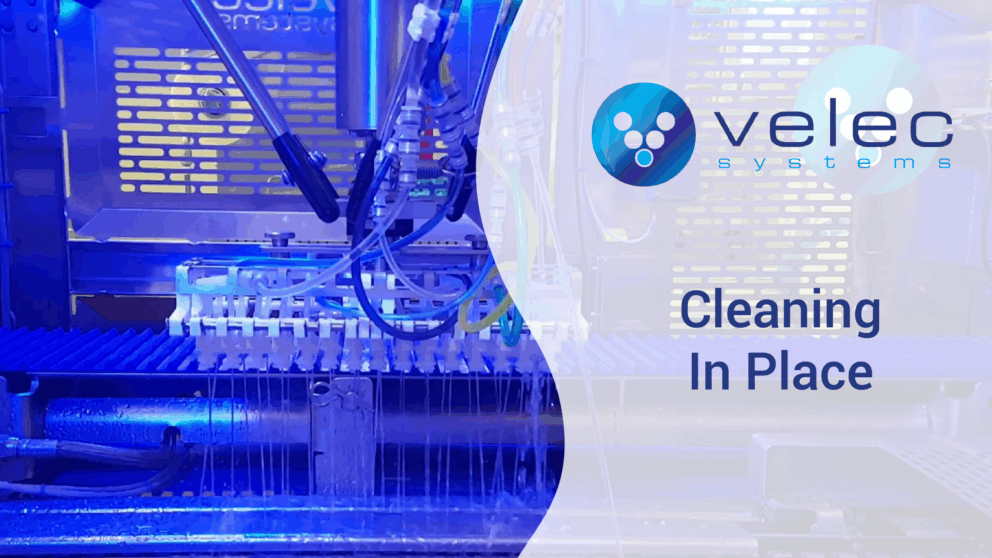

As a player in the agri-food industry, cleaning is a crucial step in your production process. You must be uncompromising on the level of hygiene of your lines! Food safety standards are strict and the risks of bacterial contamination can be high. By reducing manual handling and using a hygienic automated loading solution, you improve hygiene conditions and reduce the risk of cross-contamination. This helps you ensure food safety and strengthen customer confidence in the quality of your products.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).