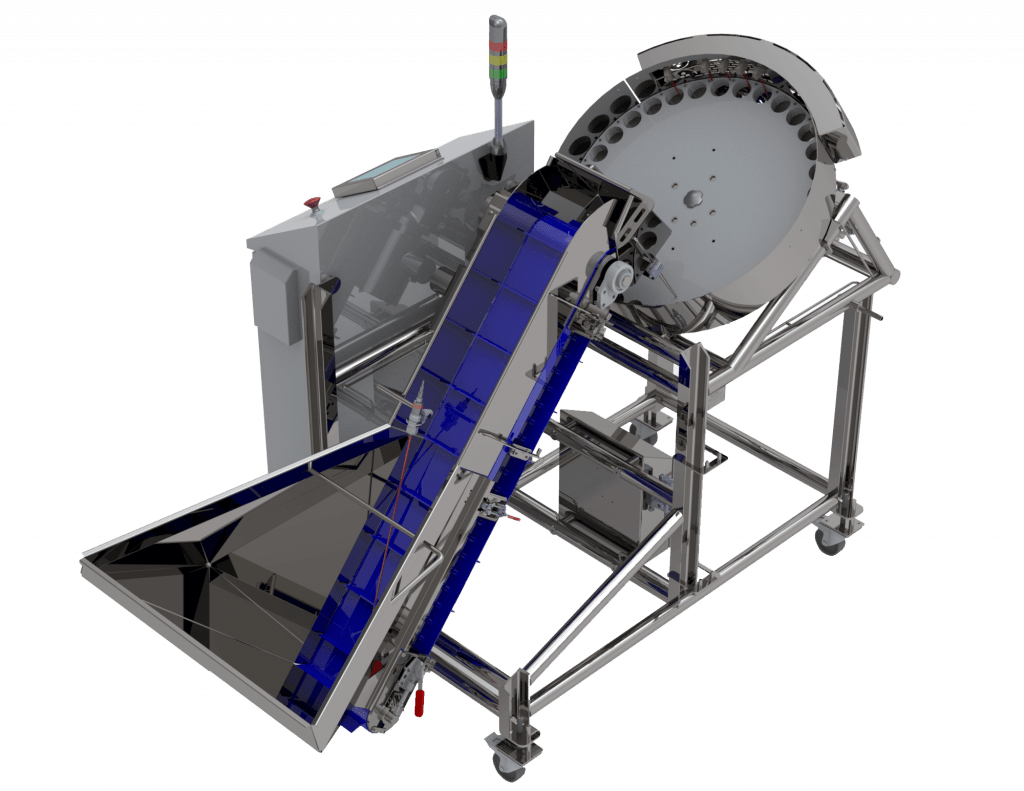

Highly flexible, our bagging solution adapts to all products and ensures the distribution of your bulk products in a perfectly ordered, controlled and timed manner.

It works in total autonomy, either in unit distribution, product dropped on the fly or in batch distribution with a dropping hooper.

It is able to load up to 21,600 products/hour

Maximize your productivity by counting your products in full autonomy

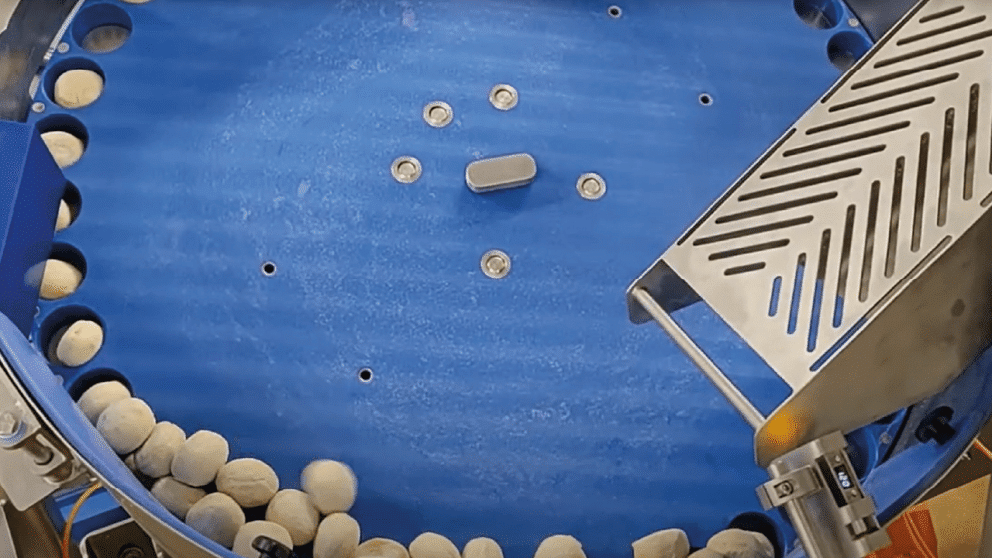

Equipped with its integrated storage hopper, the VELEC PA800 counts and brings your products automatically to the distribution trays, in full autonomy, thanks to a level detection in each tray. It aligns and counts your products at high speed.

Highly flexible, it adapts to your conditioning:

- Counting and bagging,

- Counting and canning,

- Loading into thermoforming machine

Gain in Efficiency with a Solution Custom-made to Adapt to your Production Specificities

Highly flexible, our solution offers the following features:

- Single or double disc

- Multiproduct machine with interchangeable plates

- Hopper storage capacity

- Single or multiple outputs hopper

Optimize your Operations with its Ergonomic and Compact Design

Designed to be at ground level, our solution can be installed in the narrowest spaces. It guarantees easy maintenance and cleaning. Safe and easy to use for your operators, your maintenance and cleaning operations are optimized.

Increase your OEE Thanks to the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).