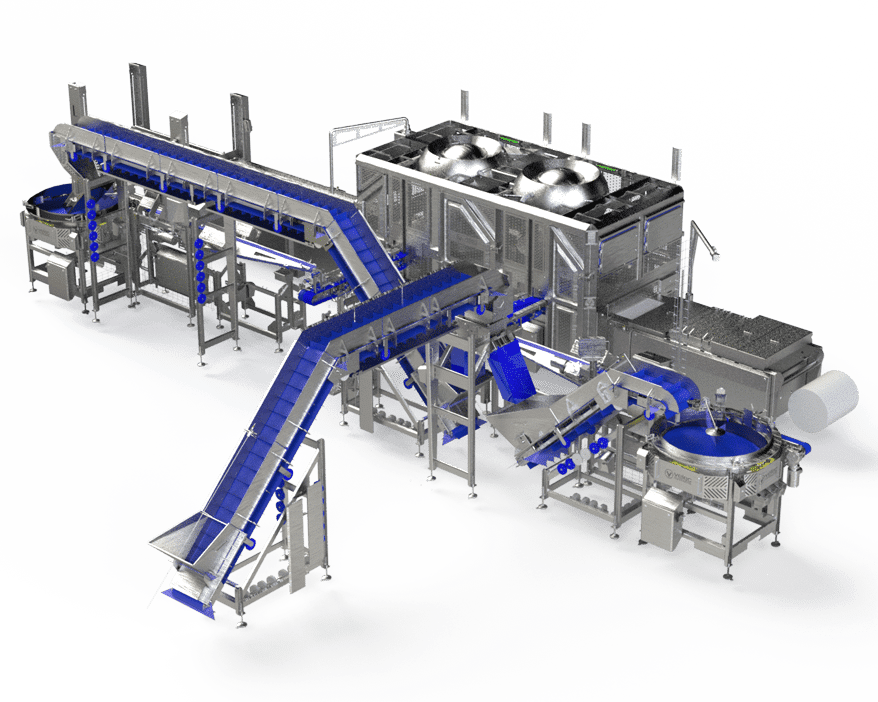

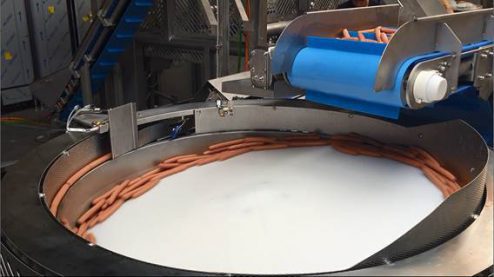

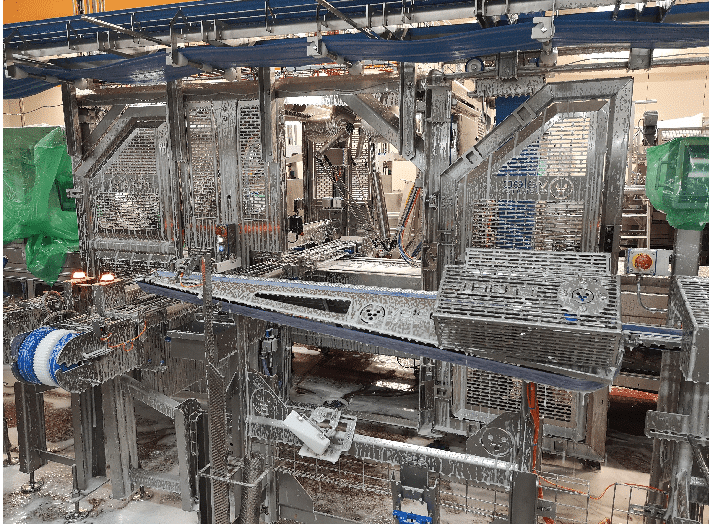

Thermoformer Loading

Loading your products into your thermoformer is a crucial step to improve your OEE. We have developed a unique and innovative solution to help you pack them in the most efficient and hygienic way.

Optimize Your Production Thanks to Our Easy-To-Use and Flexible Solution

Your operators will benefit from an easy-to-use HMI, guiding them through each step of the receipes’ changes!

- Quick setting

- No tools required

- Adaptable to unlimited recipe

- Easy and quick change over

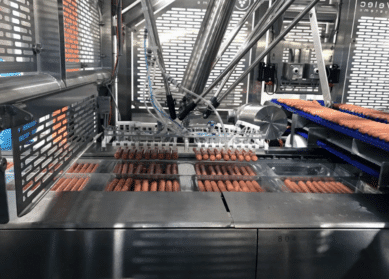

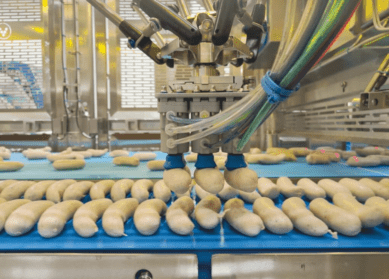

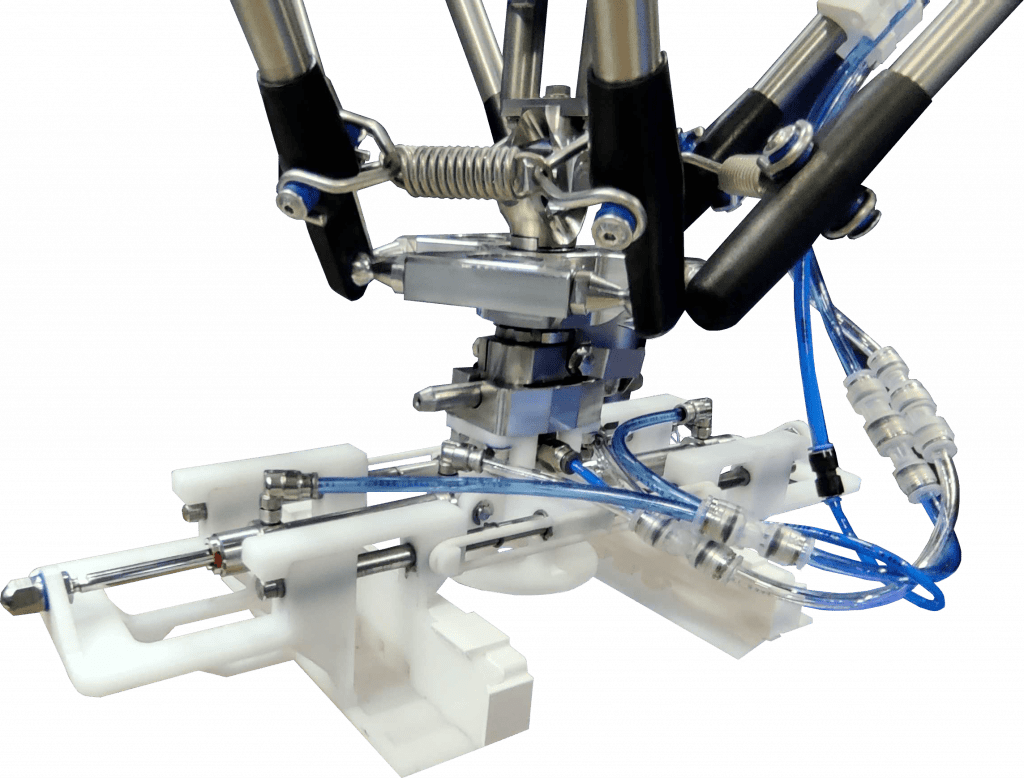

Depending on your needs and your products, we can offer various gripper technics:

- Vaccum

- Mecanic

- Needle

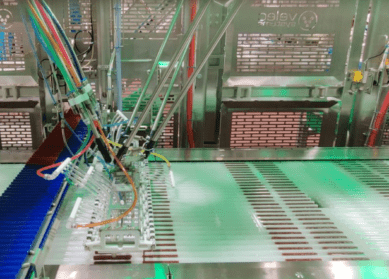

Use A High-End Equipment And Maximize And Simplify Your Cleaning Operations

As a food manufacturer, cleaning is a crucial step of your process that you can’t neglect. We can help you increase your productivity while exceeding your cleaning requirements.

Our integrated CIP solution has been designed to optimize your cleaning process and make it as easy as possible.

With the CIP program, you will no longer need to dismantle your lines to clean them: the cleaning product is sprayed directly on the surfaces, and the application times are guaranteed to ensure you gain both perfect sanitation, and efficiency!

To go further, our grippers cleaning tables are designed to facilitate your grippers and pneumatic pipes maintenance all while optimizing your operator’s time. They guarantee the flawless sanitation of your equipment.

Use a Flexible and Compact Solution That Can Load All Your Recipes!

Our solution can be very compact while loading various recipes:

- Odd or even number of products

- Various size of packaging

- Load in perpendicular or parallel way of your thermoformer, …

You name it!

Increase Your OEE Thanks to the Highest Level of Hygiene in Your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4)

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our

equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).