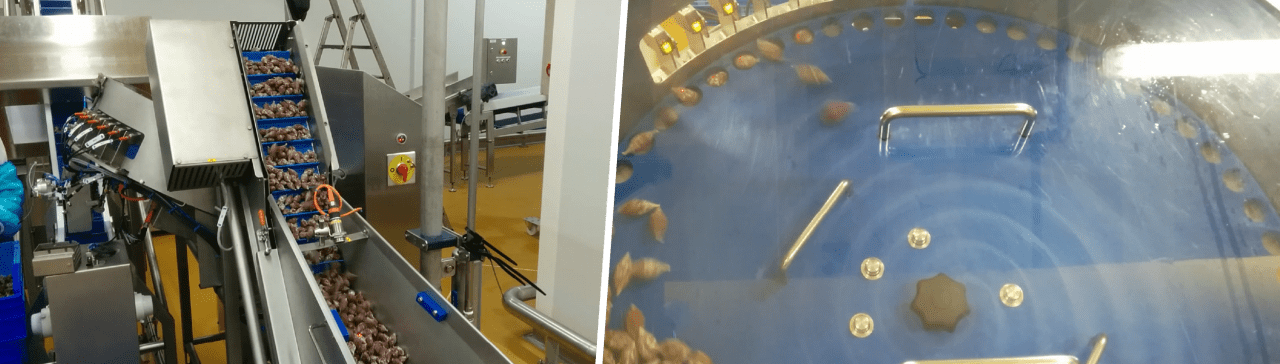

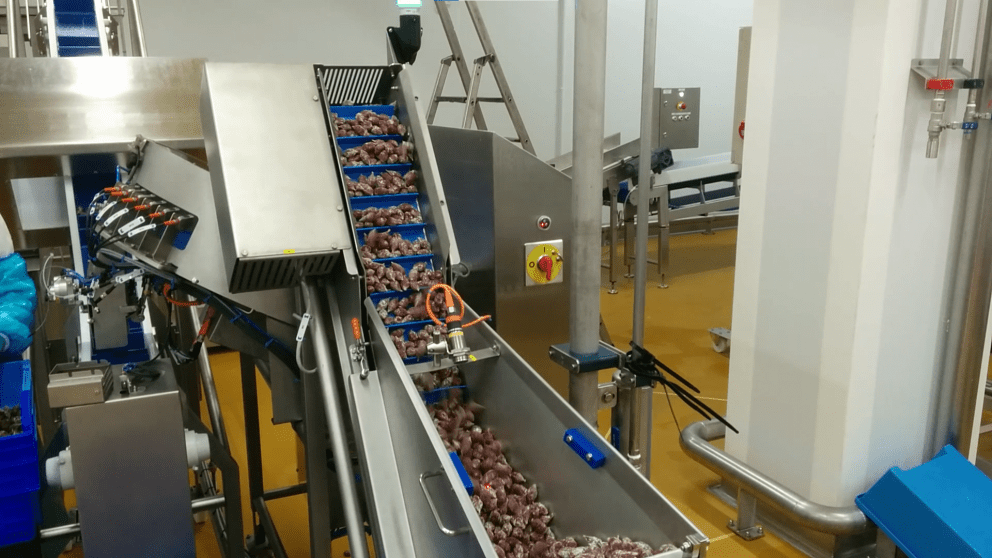

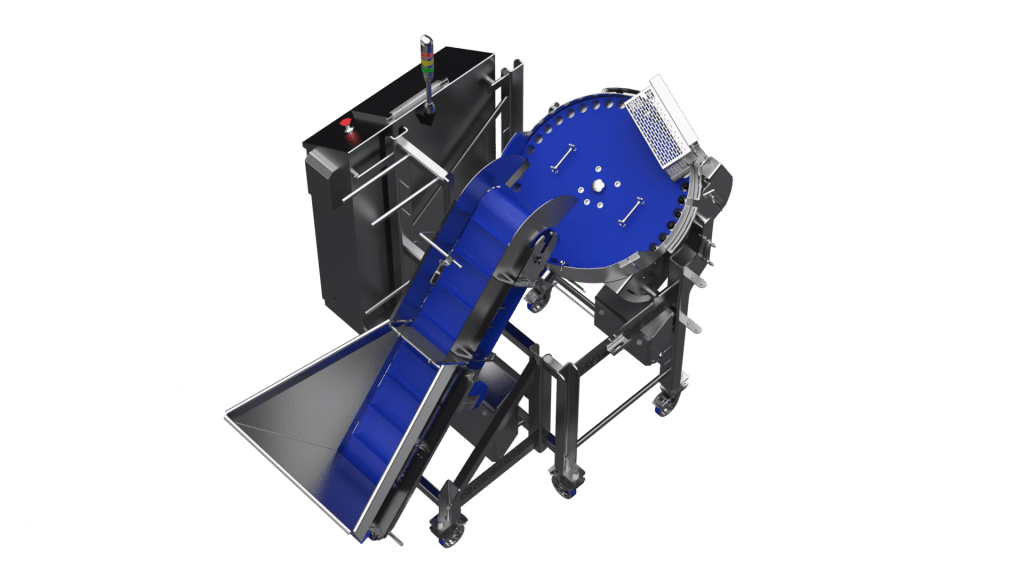

Our sausage counting solution quickly and efficiently counts sausages, increasing your production rate and reducing your costs.

Your products are distributed in a perfectly ordered, controlled and timed manner.

Up to 21,600 products/hour.

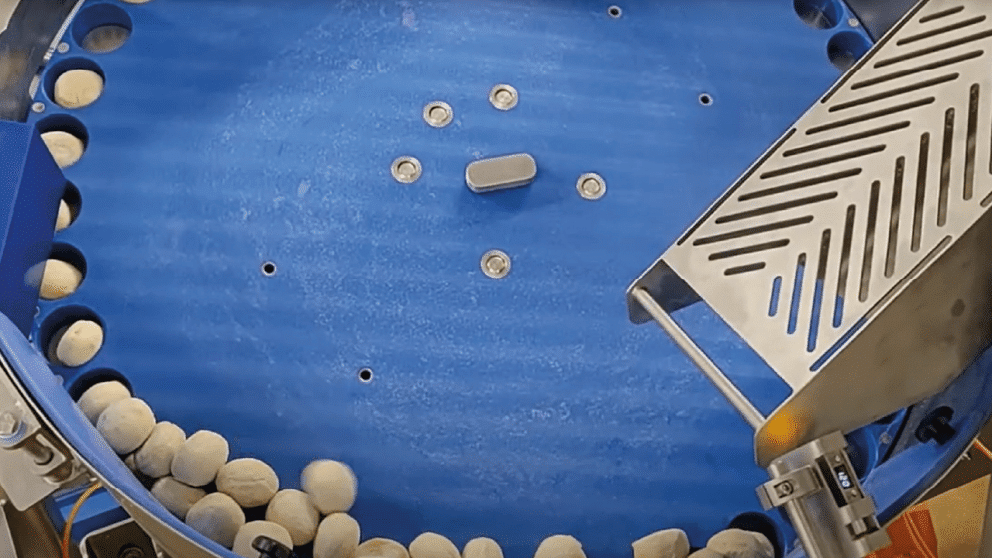

Optimize Your Production By Aligning And Counting Your Products At High Speed With Our Cellular Counting Machine

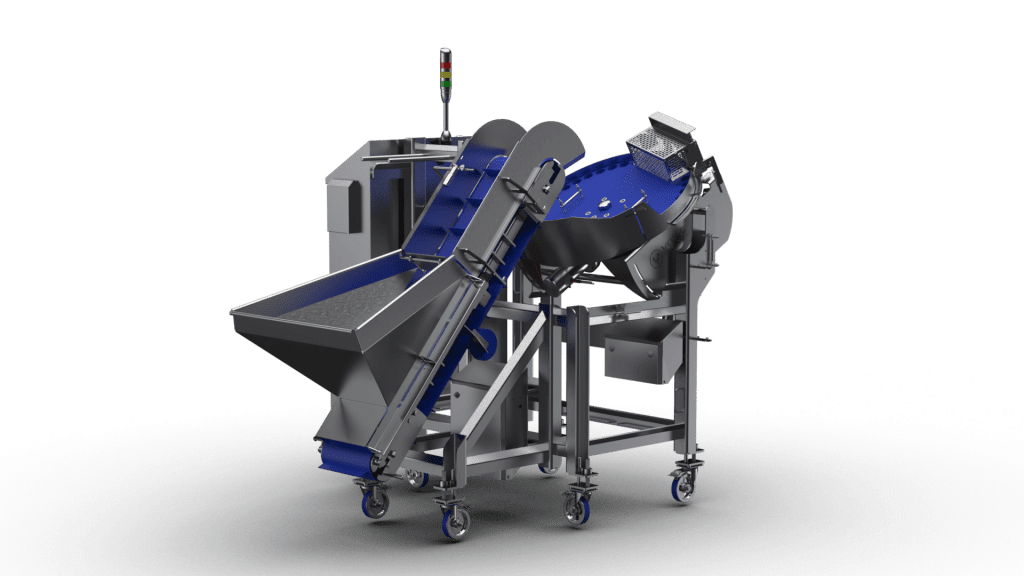

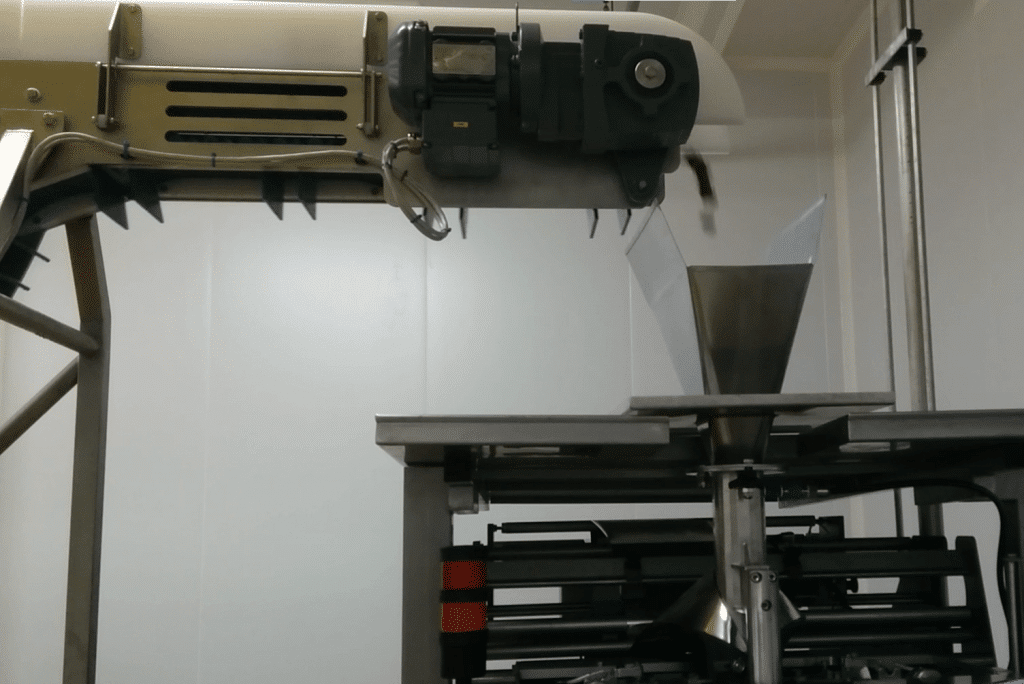

It counts and loads your products automatically on the distribution trays thanks to a level detector present on each tray. Equipped with an integrated storage hopper, the PA800 VELEC is totally autonomous and does not require the presence of operators.

Increase Your Production Line Flexibility

Designed to accommodate different types of sausages and different batch sizes, recipe changes can be made very easily with our intuitive HMI.

Highly flexible, our solution offers the following features:

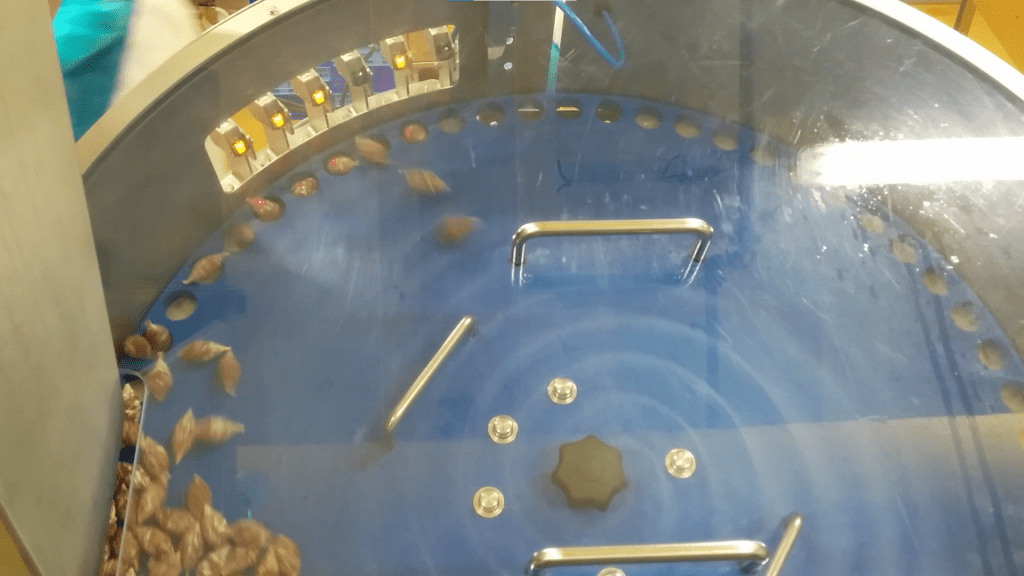

- Single or double disc

- Multiproduct machine with interchangeable plates

- Hopper storage capacity

- Metal detectors

- Multicellular output plate

Highly flexible, it adapts to your conditioning:

- Counting and bagging,

- Counting and canning,

- Loading into thermoforming machine

Take Advantage Of Its Small Footprint and Easy Access

Ergonomic, it can be installed in the narrowest spaces. Designed to be at ground level, it guarantees easy maintenance and cleaning. It is safe and simple to use for your operators.

Increase your OEE Thanks to the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).