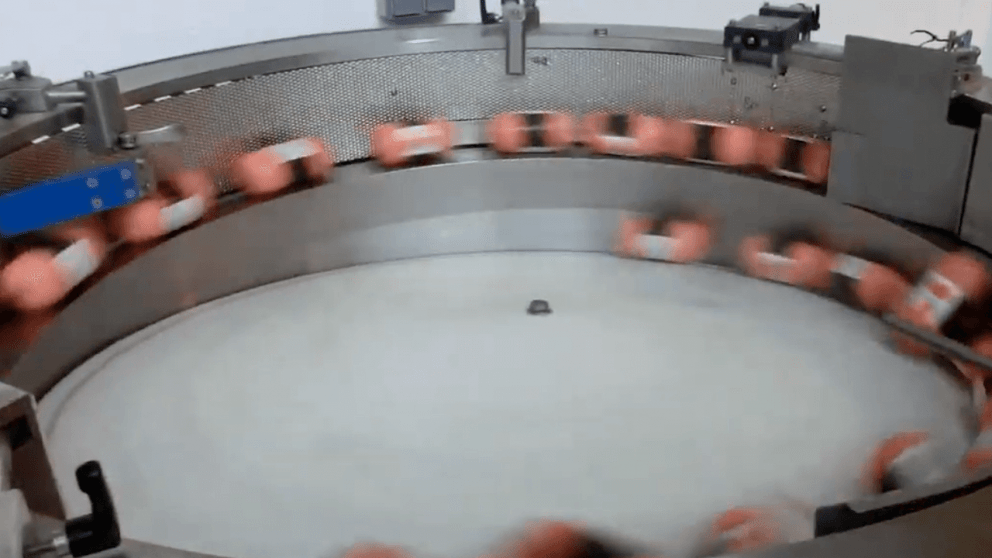

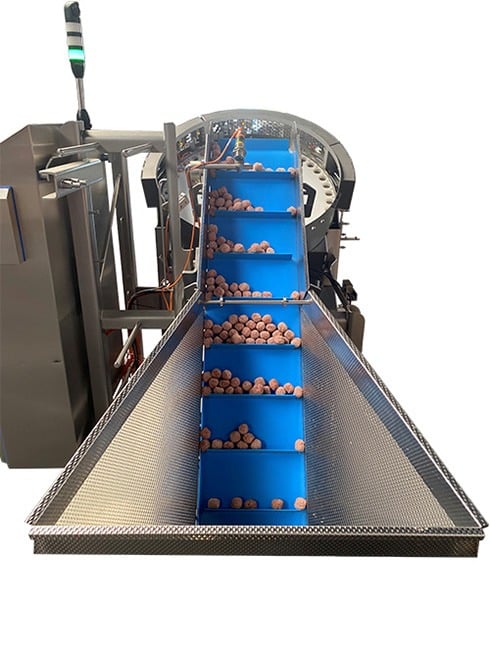

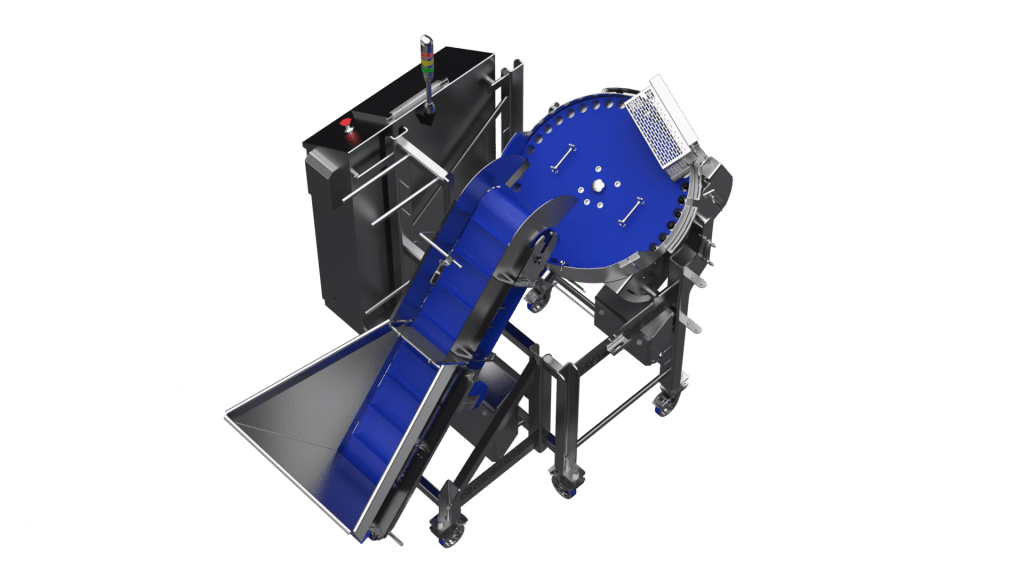

Our meatballs case packing solution counts your meatballs efficiently at high speed, allowing you to increase your production’s output and to reduce your costs.

Your products are distributed in an ordered, controlled and precise manner into your cases.

Able to go to 21,600 products/hour.

Optimize Your Production by Ordering and Counting your Products at High Speed!

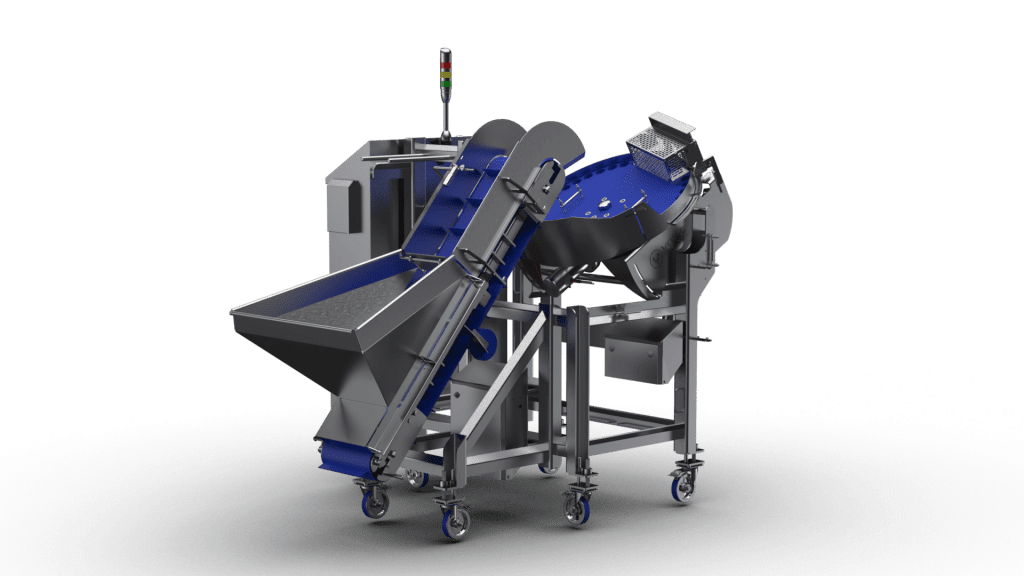

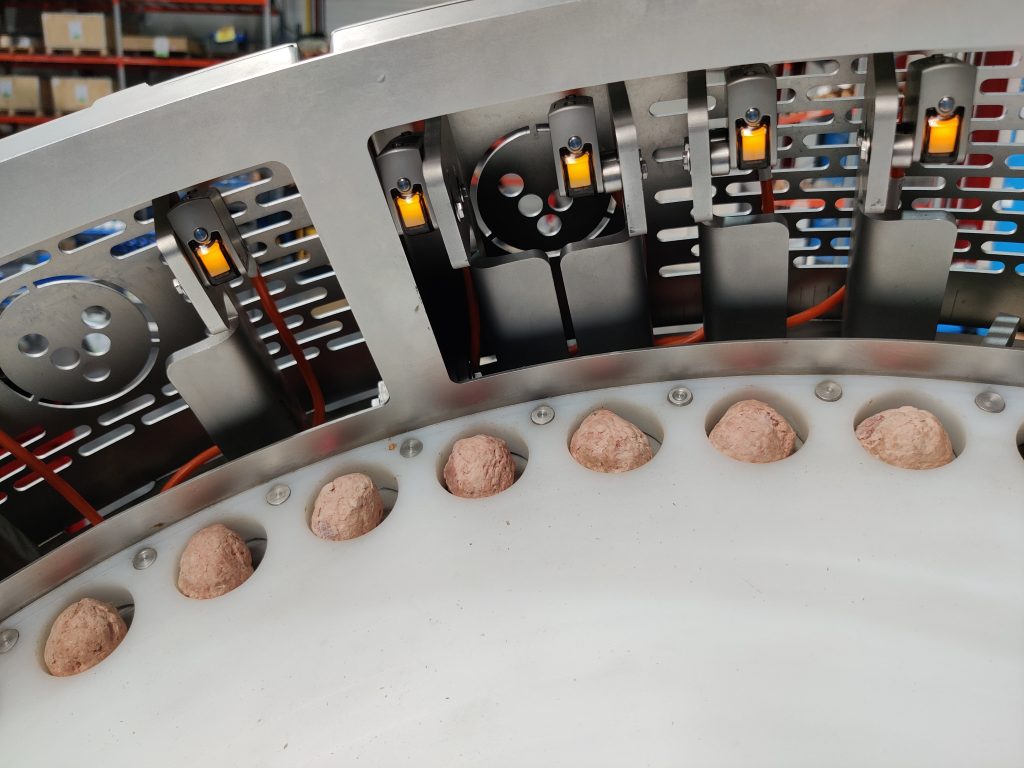

Our solution counts and loads your products automatically into distribution trays thanks to a level detector displayed on each plate. Equipped with a hopper storage, the PA800 works in full autonomy et does not require an operator’s presence.

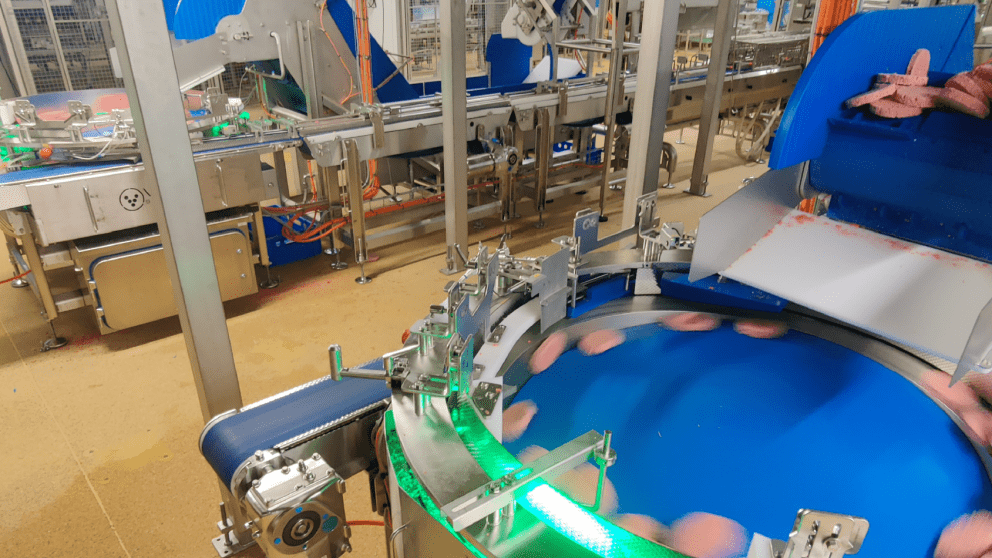

Improve your Production Lines Flexibility

Developped to adapt to your products and to different batches sizes, its recipes can be changed very easily thanks to our intuitive HMI.

- Single or double disc

- Multi-product machine with interchangeable plates

- Hopper storage capacity

- Metal detectors

- Multicellular output plate

Highly versatile, it adapts to your packaging:

- Counting and bagging

- Counting and packing

- Loading of thermoforming machine

Benefit from a Compact Solution

Thanks to its compact size, it can be installed in the narrowest places. Developped to be at ground level in order to simplify and facilitate your cleaning and maintenance operations, it ensures the safety of your operators.

Increase your OEE Thanks to our Hygienic Design Solutions!

It’s has been designed to be as easy to clean as possible. It is dismountlable without tools to simplify and maximize your cleaning operations. We are compliant and exceed the recommendations of the EHEDG (European Hygienic Engineering and Design Group).

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).