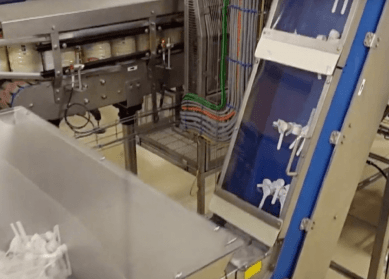

Can Feeder

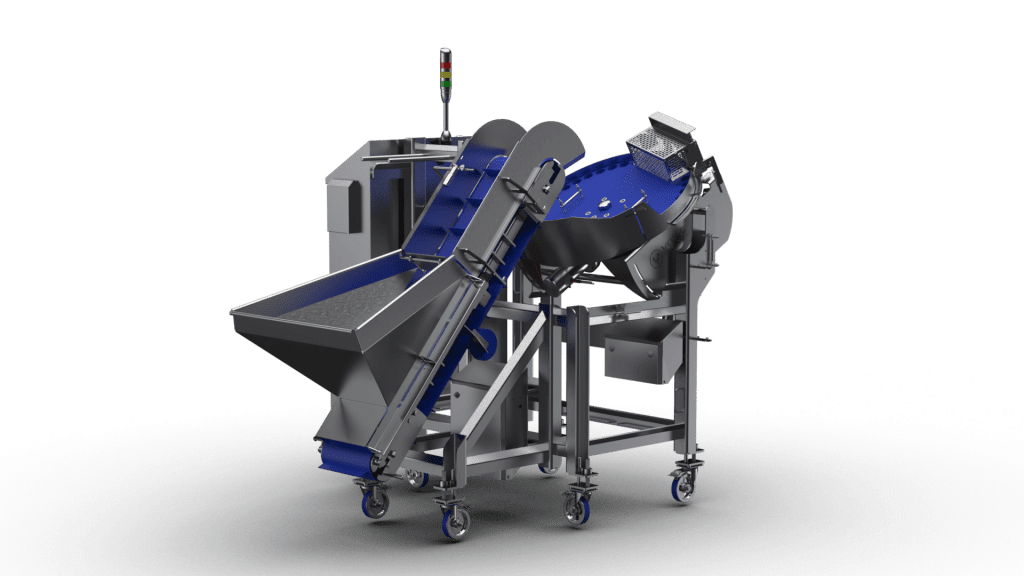

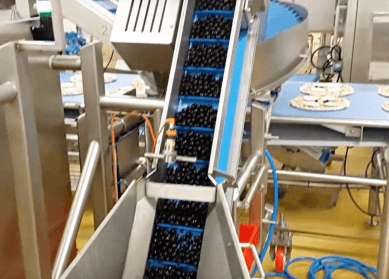

Designed and developed to align a bulk of disordered products at high speed into a continuous orderly flow.

The complete line is composed of an elevator with storage hopper, a VELEC single or double head for counting products, an output hopper, a can feeding belt. Our solution is based on centrifugal force, highly versatile and user-friendly, it is able to reach up to 21,600 products/hour

Benefit From A High Speed Solution, Custom-Made To Adapt To Your Production Specificities

Our experts designed a highly flexible and innovative solution to align a bulk of products at high speed into a perfectly ordered, controlled and precise manner. Operating either by distributing units or by distributing batches, it is able to function in full autonomy.

To best meet your needs, several options are possible:

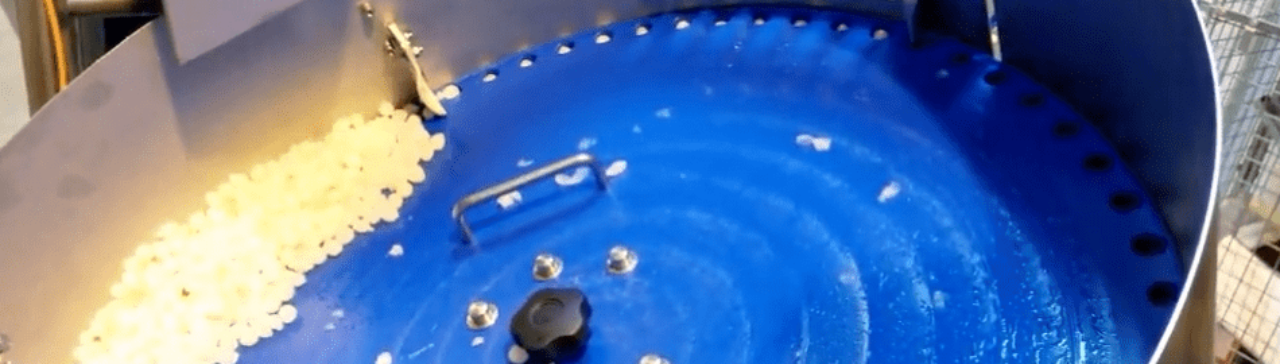

- Single or double disc

- Multi-product machine with interchangeable plates

- Hopper storage capacity

- Metal detectors

- Multi-cellular output plate

Take Advantage Of Its Small Footprint And Easy Access

The machine fits into the tightest spaces. At ground level it guarantees ease of use, supervision and maintenance for your operators and cleaning teams. It’s customizable to meet your specific needs and can be effortlessly adjusted to accommodate different can sizes and configurations. Our system seamlessly adapts to your requirements, providing you with the flexibility and versatility you need in today’s dynamic market.

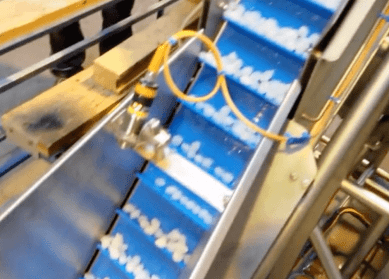

Maximize your Output Thanks to a Cutting Edge Equipment

Our can feeding system offers precise filling capabilities, ensuring each can is filled with the exact quantity of product every time. No more wastage, no more inconsistencies. With our system, you can achieve unparalleled accuracy, maintaining the quality and reputation of your products while maximizing your profits.

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4)

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our

equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).

So, let us help you streamline your operations, boost your productivity, and maximize your profitability. Together, let’s embrace the power of automation and revolutionize the way you feed and fill cans.