Think about the last stretch of your production line. By the time your products get there, you’ve already invested time, money, and effort. But here’s the catch: if the end-of-line packaging solutions aren’t up to the job, all of that hard work can unravel. A jammed case packer, a mislabeled pallet, or a time-consuming cleanup can cause costly delays—or worse, a recall.

Quick Takeaways

- End-of-line packaging solutions are profit levers, not afterthoughts.

- Hygienic design pays back every shift.

- CIP and allergen-safe changeovers protect brands.

- Data standards matter as much as machines.

- ROI is multi-dimensional.

- Conveyors are the hidden differentiator.

- Future-ready systems serve compliance and growth.

The end of the line is where your products are sealed, coded, packed, and made ready for the customer. Done well, it’s the quiet powerhouse of your plant. Done poorly, it’s a bottleneck that eats into profits.

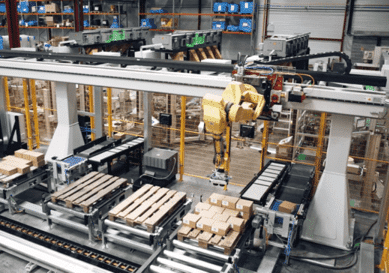

The good news? Modern systems can transform this part of your business. Hygienic conveyors that clean quickly, robotic palletizers that take the heavy lifting off your team, and smart software that keeps everything traceable and compliant—they all add up to higher throughput, safer food, and fewer headaches.

In this article, we’ll break down what end-of-line packaging really involves, why it matters, and how to choose the right fit for your operation. Along the way, you’ll get practical checklists, examples from the food industry, and tips to help you cut downtime, boost ROI, and stay ahead of regulations.

What “End-of-Line” Really Does (and Why It Matters)

The “end of the line” is where your products leave production and get ready for the outside world. By this point, they’ve been cooked, filled, sealed, or wrapped. The role of end-of-line packaging solutions is to make sure those products are protected, traceable, and ready to ship.

A typical setup includes:

- Conveyors to move cases smoothly

- Case erectors and case packers to build and fill boxes

- Checkweighers and vision systems to confirm weight, labels, and codes

- Palletizers and stretch wrappers to create stable, scan-ready pallets

When everything runs well, this stage is almost invisible. Products flow without interruption, labels are accurate, and pallets leave your dock on time. When it doesn’t, problems multiply quickly. A single breakdown in this zone can stop shipments, create rework, or even trigger compliance issues.

End-of-line is also where the last quality and safety checks happen. This is the point where labeling mistakes can be caught before products leave the building, where traceability data gets logged, and where you have the final opportunity to ensure compliance with food safety standards.

For buyers, that’s why this stage matters so much. It’s not just about moving boxes—it’s about protecting your brand and keeping your promises to customers. A strong end-of-line setup reduces downtime, prevents costly errors, and gives you confidence that everything leaving your plant is ready for the market.

What Matters Most

When you’re choosing an end-of-line system, it helps to keep your priorities clear. The equipment may be technical, but your goals as a business owner or buyer are simple: keep products moving, keep people safe, and keep customers happy. Here are the five areas that usually matter most.

1. Throughput

Every pallet that doesn’t make it onto a truck is lost revenue. End-of-line equipment needs to keep up with your upstream machines so the whole line runs smoothly. If the packer or palletizer becomes a choke point, your production goals will slip no matter how fast the rest of the line runs.

2. Hygiene

Food safety never stops at the filler or the oven. Case conveyors, palletizers, and labelers all have to stand up to washdowns and cleaning routines. Look for hygienic designs with stainless steel, open frames, and quick-release belts. A system that’s easy to clean not only protects your product but also saves hours of sanitation time every week.

3. Labor and Ergonomics

Manually stacking cases is exhausting and risky. Automated palletizers and case packers reduce injuries and free up workers for higher-value tasks. With labor shortages in the food industry, automation isn’t just about efficiency—it’s about making sure you can keep your line staffed.

4. Traceability and Compliance

New food safety rules like FSMA 204 mean you need to track and store more data at the end of the line. The right systems can scan, record, and link product information automatically, giving you peace of mind if there’s ever a recall or audit.

5. Footprint

Floor space is always at a premium. Integrated cells that combine case packing, palletizing, and wrapping can save valuable square footage while delivering the same—or greater—capacity.

Keeping these priorities in mind makes it easier to compare options and ask the right questions. The best solution isn’t always the one with the highest speed—it’s the one that balances throughput, hygiene, labor savings, traceability, and space in a way that fits your operation.

Hygienic Design: Your First Line of Defense

In food packaging, clean equipment isn’t optional—it’s your first safeguard against recalls and downtime. The end of the line is no exception. Conveyors, packers, and palletizers all touch cases, labels, or pallets that will head directly into storage or onto trucks. If these systems aren’t designed for easy cleaning, they can quickly become a weak point in your operation.

What should you look for?

- Stainless steel everywhere. Painted frames and hidden corners are hard to clean and can trap contaminants. Stainless steel holds up better and meets food industry standards.

- Open, angled frames. Flat or closed designs collect water and debris. Open, sloped surfaces let water drain and make inspection simple.

- No hollow tubing. Hollow bodies can harbor bacteria. Solid or sealed structures are safer and easier to maintain.

- Quick-release belts and parts. The faster you can remove belts or guards without tools, the less time your crew spends on sanitation.

- IP69K-rated motors and sensors. These components can withstand high-pressure washdowns without failing—critical for consistent uptime.

- For Best Practices in Layout and Modularity, see Smarter Conveyor Design for Food Packaging Efficiency

Why does all this matter? Because time is money. If sanitation takes two hours instead of one, that’s an hour of lost production every single day. Hygienic design not only keeps you compliant with food safety regulations but also gives you back valuable production time.

For buyers, here’s the bottom line: investing in hygienic end-of-line packaging solutions saves money long after installation. You’ll spend less on cleaning, less on replacement parts, and far less worrying about the risk of a food safety issue.

CIP and Allergen-Safe Changeovers: Faster, Safer, Audit-Ready

If your plant runs multiple products, you already know how much time is lost during changeovers. And if those products contain different allergens—like dairy, nuts, or sesame—the stakes are even higher. A missed crumb or a mislabeled case can trigger a costly recall.

That’s why more food manufacturers are looking at clean-in-place (CIP) systems for their end-of-line equipment. Instead of tearing down conveyors or scrubbing everything by hand, CIP automates the process. With the push of a button, the system rinses, washes, and sanitizes equipment in a controlled cycle. The result is faster changeovers, consistent cleaning, and detailed records you can show during audits.

Here’s what to look for in allergen-safe changeovers:

- Automated cleaning cycles. CIP reduces water, chemical, and labor use while keeping results consistent.

- Tool-free disassembly. Belts and guards should pop off quickly for visual checks—no wrenches required.

- Recipe-driven setups. Operators can select the right product on the HMI, and the system adjusts settings to match.

- Label and code verification. Vision systems can catch wrong allergen statements before a case leaves the building.

The payoff is more than convenience. Faster changeovers mean more production time every week. Automated cleaning reduces human error and gives you a digital log of each cycle. And with allergen recalls among the most common in the industry, those records are priceless when inspectors come calling.

For buyers, the key takeaway is simple: CIP-ready end-of-line packaging solutions save both time and risk. They free your team from repetitive cleaning tasks, protect your brand, and keep your line running longer between stops.

Controls and Integration: PackML + OPC UA ≠ Buzzwords

A packaging line isn’t just about machines. It’s about how those machines talk to each other. If your case packer, palletizer, and labeler don’t share information, you’ll end up with gaps, delays, and frustrated operators. That’s why integration matters just as much as the equipment itself.

Modern systems often use something called PackML and OPC UA. Don’t worry about the acronyms—here’s what they mean in practice:

- PackML gives every machine a common “language” for states like start, stop, fault, or changeover.

- OPC UA is the secure connection that allows this information to flow between machines and up to your plant systems.

When equipment follows these standards, integration is faster, and troubleshooting is easier. For you, that means less custom coding, fewer headaches during startup, and clearer data to manage your operation.

Good integration also lays the foundation for real-time OEE monitoring. Instead of guessing why your line is running slow, you can see exactly where downtime is coming from and act on it.

Here’s what to ask suppliers about integration:

- Can their machines share standard data tags with your other equipment?

- Do they support open communication protocols, or do they rely on proprietary systems?

- Will the system make it easier to connect to your ERP, MES, or traceability software?

The bottom line: machines that can’t talk to each other will cost you time and money. Choosing integrated, standards-based solutions gives you flexibility today and future-proofs your operation for tomorrow.

Conveyor Design: The Unsung Hero of EOL Performance

Conveyors don’t usually grab headlines, but they make or break the end of your line. A poorly designed conveyor can cause jams, starve your case packer, or flood your palletizer. A well-designed conveyor, on the other hand, keeps everything moving smoothly and quietly in the background.

Here’s what to look for when evaluating conveyor design:

- Smooth product flow. Accumulation zones before key machines help absorb small hiccups upstream so the whole line doesn’t stop.

- Hygienic construction. Stainless steel, open frames, and sloped surfaces prevent water and debris from collecting. This makes cleaning faster and reduces contamination risk.

- Quick-release belts. Belts and guides that can be removed without tools save valuable sanitation time.

- Ergonomics. Conveyors should be positioned so your team can work without bending, reaching, or lifting awkwardly.

- Flexibility. Modular conveyors allow you to add, move, or reconfigure sections as your line changes.

Why does this matter? Because the conveyor is the thread that ties your end-of-line systems together. If it’s unreliable, everything downstream suffers. If it’s hygienic and easy to maintain, you save hours of downtime every week.

For buyers, the real insight is this: conveyors aren’t just “the in-between.” They are the backbone of your end-of-line packaging solutions. A smart conveyor layout keeps your high-value equipment running at full capacity, improves operator safety, and helps you meet hygiene standards with less effort.

Conclusion

End-of-line packaging isn’t just the “last step” in production—it’s the safeguard that determines whether your products reach customers safely, compliantly, and profitably. As we’ve seen, the right end-of-line packaging solutions do far more than move boxes. They streamline throughput, reduce labor strain, and cut sanitation time with hygienic designs built for the food industry. They also prepare your operation for the future by embedding FSMA 204–ready traceability and data integration, ensuring you can meet evolving regulatory and customer demands with confidence.

When evaluated only on speed, equipment comparisons may seem straightforward. But the real ROI comes from eliminating micro-stops, shortening allergen changeovers, reducing recalls, and lowering lifetime maintenance costs.

Velec Systems specializes in hygienic, conveyor-first end-of-line solutions designed for food environments. If you’re ready to boost OEE, simplify compliance, and future-proof your packaging line, request a free End-of-Line Audit today and see where hidden profits can be unlocked.

References

U.S. Food and Drug Administration. FSMA Final Rule: Additional Traceability Records (FSMA 204).

Food Engineering (QAD). FSMA 204: The Clock Is Ticking…

Packaging Technology Today. Aligning Compliance with GS1 Integration

Velec Systems. Why OEE Matters in Food Processing

Velec Systems. Conveyor Design for Food Packaging: Boost End-of-Line ROI

Velec Systems. Hygienic Design

Velec Systems. UV Lights Cleaning Solution

Velec Systems. Hygiene and Efficiency: The Role of Clean-In-Place Equipment