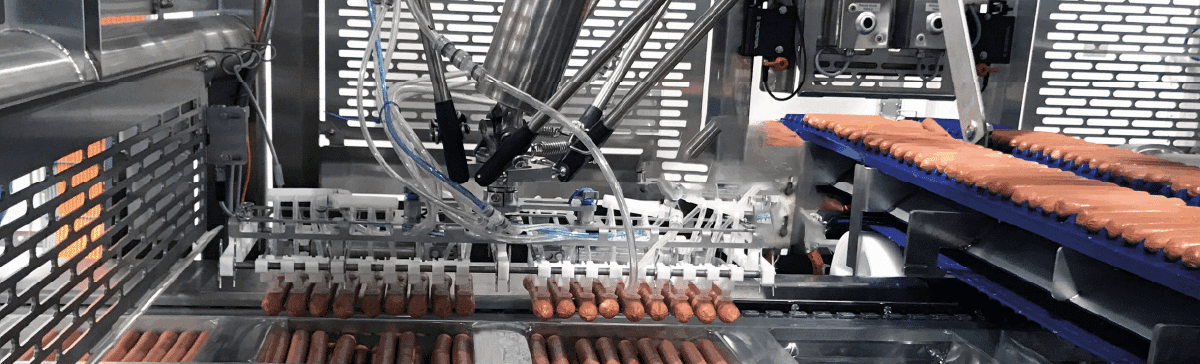

In today’s fast-paced food production landscape, even a few minutes of downtime can disrupt an entire packaging schedule. For meat processors and packaging plant managers, one critical piece of the line often flies under the radar, until it fails: the hot dog loader. This essential component ensures a seamless handoff between production and packaging, aligning and loading products efficiently and hygienically. Yet without proper care, even the best equipment can become a bottleneck.

If you’re a CEO or procurement lead aiming to boost line reliability, or an operations manager responsible for maximizing uptime, effective hot dog loader maintenance is your hidden advantage. From minimizing unexpected breakdowns to ensuring compliance with hygienic design standards, small maintenance actions have a significant business impact.

In this article, we’ll walk you through everything you need to know: preventive maintenance routines, daily cleaning checklists, operator training tips, and how to recognize the signs of wear before they lead to costly failures. We’ll also explore how Velec Systems’ loader designs simplify maintenance through hygienic construction, smart alerts, and tool-less access. Let’s keep your line moving, and your margins strong.

Quick Takeaways: Hot Dog Loader Maintenance Essentials

- Routine maintenance reduces downtime and extends the life of your hot dog loader, saving thousands in unexpected repair costs and lost production time.

- Hygienic design matters. Loaders built with 304 or 316 stainless steel and CIP-ready features simplify cleaning and reduce contamination risk, meeting USDA and EHEDG standards.

- Preventive maintenance beats reactive fixes. Daily visual inspections, weekly lubrication, and sensor checks help you catch wear before it causes failure.

- Operator training is a profit lever. Well-trained staff can spot issues early, follow SOPs for sanitation, and contribute to smoother operations with fewer stoppages.

- Smart features drive smarter uptime. Modern loaders with HMI alerts, modular parts, and tool-less access speed up diagnostics and cleaning routines.

- Common failure points—like actuators, belts, and loading arms—must be monitored regularly to prevent cascading issues across the packaging line.

- Partnering with OEMs like Velec Systems ensures you’re supported by expert guidance, spare parts availability, and equipment designed for real-world meat packaging demands. Explore our Cooked Sausage Loader for detailed specifications.

Core Maintenance Objectives for Hot Dog Loaders

Maximize Equipment Uptime

The most critical objective in hot dog loader maintenance is ensuring that the equipment operates smoothly without interruption. Maximizing uptime prevents the costly delays that result from equipment failure, which can lead to production bottlenecks and delayed product deliveries. A well-maintained hot dog loader will keep your packaging line running at peak efficiency, avoiding unexpected downtime.

Ensure Product Safety and Compliance

Hygiene is paramount in the food industry. A clean, well-maintained hot dog loader helps prevent contamination and ensures compliance with regulatory standards like USDA and EHEDG. Regular maintenance routines, including cleaning and sanitation, are essential to maintaining food safety standards and ensuring the quality of your product.

For instance, equipment that’s easy to clean and has smooth, non-porous surfaces prevents the accumulation of food residues or harmful microorganisms, which could lead to contamination or product recalls. Velec’s hygienic design features allow for quick clean-in-place (CIP) procedures, which ensure sanitary conditions without disassembling the equipment.

Extend Equipment Life

By performing regular preventive maintenance, you can extend the lifespan of your hot dog loader. Preventive maintenance reduces wear and tear on critical components like belts, actuators, and sensors, thereby saving money on expensive repairs or replacements. The longer your equipment lasts, the better the return on investment.

Regular checks of key components and replacing them before they reach the end of their life can drastically reduce operational costs. With Velec’s tool-less access and smart design, maintaining your loader is simple and can be done quickly by in-house maintenance teams, extending the equipment’s service life.

Preventive vs. Reactive Maintenance Strategies

Why Preventive Maintenance Is Essential

Preventive maintenance (PM) involves regular inspections and part replacements based on a pre-determined schedule, allowing you to address issues before they cause a breakdown. A well-implemented PM strategy can significantly reduce downtime and extend the life of your hot dog loader. As highlighted in the industry, “the cost of preventive maintenance is always lower than the cost of repairs caused by neglect” (source: Velec Systems – Hot Dog Loader).

Reactive Maintenance: When It’s Too Late

Reactive maintenance occurs when equipment breaks down unexpectedly, often resulting in costly repairs and prolonged downtime. While it’s impossible to avoid reactive maintenance entirely, relying solely on this approach can damage your production efficiency and bottom line. Learn about our Preventive Maintenance Services to ensure optimal performance.

Integrating Predictive Sensors and Smart Alerts

Modern hot dog loaders are equipped with smart sensors that monitor operational performance in real-time. These sensors can provide early warnings of potential issues, allowing operators to take corrective actions before major failures occur. Predictive maintenance tools are a great way to combine preventive and reactive strategies.

Daily Maintenance Checklist for Line Operators

Visual Inspection Points

Start each day with a quick visual inspection to ensure that the loader is functioning as expected. Check for signs of wear on the conveyor belts, pneumatic actuators, and loading arms. If any issues are detected, report them immediately to avoid further damage.

Surface Cleaning Protocols

Maintaining cleanliness is critical for both food safety and loader efficiency. Implement daily cleaning protocols that include sanitizing all food-contact surfaces. Use food-safe cleaning agents that won’t damage the equipment or leave harmful residues.

Lubrication and Component Wear Check

Ensure that all moving parts are properly lubricated, including bearings, gears, and pneumatic systems. Regular lubrication prevents friction, which can cause premature wear. Additionally, check for any unusual vibrations or noises that may indicate a part is beginning to fail.

Recordkeeping and Maintenance Logs

Maintain a log of all maintenance activities, including inspections, cleanings, and parts replacements. This will help track the maintenance history of the loader and ensure that nothing is overlooked.

Hygienic Design Considerations That Simplify Maintenance

Stainless Steel Selection: 304 vs. 316

The best materials for food processing equipment are those that resist corrosion and are easy to clean. Stainless steel grades 304 and 316 are commonly used in the construction of hot dog loaders. Grade 316 is particularly resistant to corrosion caused by acidic foods and cleaning agents, making it ideal for high-hygiene environments. Discover the importance of Hygienic Design Solutions in equipment maintenance.

Surface Finish Requirements for Cleanability

The surface finish of the loader is a crucial factor in its ability to be thoroughly cleaned. Smooth, non-porous surfaces are essential to avoid food particles and bacteria getting trapped in hard-to-reach areas. A surface roughness of Ra < 0.8 μm is typically recommended for food-contact surfaces (source: EHEDG Hygienic Design Guidelines).

Access Panels, Seals, and Drainage

Ensure that access panels are easy to remove, and that seals are in place to prevent contamination. Self-draining systems that allow fluids and food particles to be flushed away without buildup are a must-have for efficient sanitation.

Avoiding Dead Zones and Biofilm Risk

Dead zones are areas where food particles, water, or air can accumulate, creating an environment for bacteria growth. Avoid dead zones in the loader’s design by ensuring proper drainage and easy access for cleaning.

Safety Protocols During Maintenance

Lockout/Tagout Procedures

Before performing any maintenance or repair work, follow proper lockout/tagout (LOTO) procedures to ensure that all power sources are disconnected. This prevents accidents and ensures worker safety during maintenance tasks.

Handling Sharp Edges and Hot Surfaces

Hot dog loaders often involve heated components. Always take precautions when handling equipment with sharp edges or hot surfaces. Use PPE (Personal Protective Equipment) such as gloves and safety glasses to prevent injury.

Proper PPE Use and Emergency Stop Testing

Ensure that workers are wearing the appropriate PPE for each task. Regularly test the emergency stop mechanisms to ensure they function properly in case of an emergency.

Conclusion: Maintenance is More Than a Chore—It’s a Strategic Advantage

In high-volume meat processing, equipment failure isn’t just inconvenient—it’s expensive. As we’ve explored, hot dog loader maintenance is not merely about keeping machines clean and running—it’s about safeguarding your bottom line, your brand reputation, and your ability to deliver consistent quality at scale.

By implementing structured preventive maintenance routines, investing in operator training, and choosing loaders with hygienic, easy-to-clean designs, you’re not just preventing downtime—you’re creating competitive resilience. Loaders designed with CIP-ready systems, tool-less access, and stainless-steel construction (304 or 316) allow for faster sanitation and less risk of contamination. And with smart HMI alerts and modular parts, troubleshooting becomes proactive, not reactive.

For CEOs and plant managers, the key takeaway is this: the cost of inaction far exceeds the cost of maintenance. A well-maintained hot dog loader doesn’t just keep your line moving—it protects your margins and ensures every product shipped reflects your commitment to safety and excellence.

Ready to reduce downtime and boost performance?

👉 Contact Velec Systems today to schedule a consultation or request a customized loader maintenance checklist tailored to your facility’s needs.

References

Viking Masek. (n.d.). 5 Expert Tips for Proper Packaging Machine Maintenance. Retrieved from https://vikingmasek.com/packaging-machine-resources/packaging-machine-blog/5-expert-tips-for-proper-packaging-machine-maintenance

Velec Systems. (n.d.). Hot Dog Loader Product Page. Retrieved from https://www.velecsystems.com/en/solution_complete/meat/hot-dog-loader/

Velec Systems. (n.d.). Hygienic Design Solution for Food Production. Retrieved from https://www.velecsystems.com/en/hygienic-design/

Velec Systems. (n.d.). The Role of Clean-In-Place Equipment in Meat Packaging Lines. Retrieved from https://www.velecsystems.com/en/hygiene-and-efficiency-the-role-of-clean-in-place-equipment-in-meat-packaging-lines/

Velec Systems. (n.d.). Optimizing Sausage Packaging: Centrifugal Machines & TCO. Retrieved from https://www.velecsystems.com/en/optimizing-sausage-packaging-centrifugal-machines-tco/

Skjöldebrand, C. (2013). Chapter 3: Food-Processing Equipment. In C.G.J. Baker (Ed.), Handbook of Food Factory Design. Springer.

Baker, C.G.J. (2013). Chapter 4: Hygienic Design of Food-Processing Equipment. In C.G.J. Baker (Ed.), Handbook of Food Factory Design. Springer.

Baker, C.G.J. (2013). Chapter 7: Safety and Health. In C.G.J. Baker (Ed.), Handbook of Food Factory Design. Springer.

European Hygienic Engineering & Design Group (EHEDG). (n.d.). Hygienic Design Guidelines. Retrieved from https://www.ehedg.org/guidelines-working-groups/guidelines/guidelines/detail/hygienic-design-principles

Black Forest Packaging Solutions. (2023, February 9). Tips for Preventative Maintenance on Food Packaging Machines. Retrieved from https://blackforestpkg.com/2023/02/09/tips-for-preventative-maintenance-on-food-packaging-machines/

Velec Systems. “Maximizing Sausage Packaging Efficiency with Automation.” Available at: https://www.velecsystems.com/en/optimizing-sausage-packaging-centrifugal-machines-tco/