Palletizing Solutions for Food Manufacturers: Efficiency, Safety, and ROI

Efficiency is everything. From raw ingredients to finished products, every step of the process impacts your bottom line. Yet one stage often overlooked is the very last: stacking products onto pallets for storage or shipment. Traditionally done by hand or with basic machinery, this step can slow production, strain your workforce, and compromise consistency. That’s where palletizing solutions come in.

Modern palletizing systems—whether robotic, conventional, or hybrid—do far more than stack boxes. They reduce labor costs, improve worker safety, ensure hygienic handling, and keep your production lines running around the clock. For food business owners and buyers, investing in automated palletizing is no longer a luxury—it’s a competitive advantage.

Quick Takeaways

- Palletizing solutions are essential for food manufacturers — they improve efficiency, ensure worker safety, and keep end-of-line operations consistent.

- Modern palletizing systems go beyond stacking boxes by integrating robotics, vision inspection, and software to handle diverse packaging formats and ensure food safety compliance.

- Robotic palletizers deliver flexibility and scalability, making it easier to adapt to SKU changes, seasonal demand, and mixed product loads without major reconfiguration.

- Automated palletizing drives ROI quickly, with many food businesses seeing payback in 6–18 months thanks to labor savings, reduced downtime, and improved throughput.

- Hygienic, washdown-ready designs are critical in the food industry, ensuring compliance with FSMA, EHEDG, and allergen-control standards.

- Integration is key — the most effective palletizing systems connect seamlessly with conveyors, case packers, and Industry 4.0 dashboards for full end-of-line traceability.

- Choosing the right partner matters — Velec Systems offers turnkey solutions, tailored to different food segments, that prioritize hygiene, flexibility, and long-term reliability.

In this article, we’ll explore the types of palletizing systems available, the technology behind them, and the specific benefits they bring to food manufacturers. We’ll also address key buyer concerns, from ROI and installation downtime to hygiene compliance and integration with existing equipment. Finally, we’ll highlight why choosing the right partner—like Velec Systems—can make all the difference in building a smarter, safer, and more profitable end-of-line packaging process.

2. What Is Palletizing?

Palletizing is the process of stacking packaged products onto a pallet for storage, transportation, or distribution. In food manufacturing, this final stage of production is far more than just logistics—it’s a critical factor in efficiency, safety, and product integrity.

For decades, many food producers relied on manual palletizing, where workers would lift and arrange cases by hand. While effective for small volumes, this approach is slow, labor-intensive, and poses serious risks of repetitive strain injuries.

Over time, manufacturers introduced conventional palletizers, which use mechanical conveyors and row-forming equipment to organize products into neat layers. These systems can handle high throughput, making them ideal for uniform product lines like canned vegetables or bottled beverages. But conventional palletizers struggle with today’s diverse food packaging formats, from fragile bakery goods to mixed-case frozen meals.

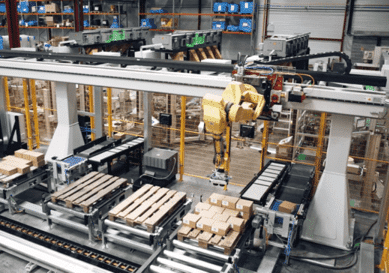

That’s where robotic palletizing solutions enter the picture. Robotic palletizers use articulated arms, advanced gripper technologies, and vision systems to adapt to different packaging sizes and shapes. For example, a robotic cell might pick up delicate cartons of dairy products in the morning, then switch to heavier cases of frozen sausage packs in the afternoon—all without major reconfiguration.

One unique benefit often overlooked is how palletizing directly affects downstream logistics. Poorly stacked pallets increase the risk of product damage during transit, leading to waste and costly returns. Automated palletizing ensures consistency and stability, reducing both transportation risks and insurance costs. At Velec Systems, palletizing solutions are designed with quality control software that verifies load stability and traceability before pallets leave the line—something many older systems cannot provide.

In short, palletizing is not just about “moving boxes.” It’s a strategic stage that connects your production floor to your distribution network. By moving from manual or semi-automatic approaches to advanced robotic palletizers, food manufacturers can safeguard workers, reduce waste, and improve the reliability of every order shipped.

3. Types of Palletizing Solutions

Conventional Palletizers

Conventional palletizers are built for speed and uniformity. They use conveyors and row-forming systems to create structured layers of cartons, crates, or bags. These systems excel in high-throughput environments where packaging is consistent, such as beverage bottling plants. However, they lack flexibility for today’s food manufacturers dealing with varied SKUs and packaging types.

Robotic Palletizers

Robotic palletizers are highly flexible, using articulated arms and custom grippers to handle multiple formats. They can switch between heavy cartons, delicate bakery trays, or shrink-wrapped frozen goods with minimal downtime. This adaptability makes them ideal for modern production lines where consumer demand changes frequently.

Hybrid & Specialized Systems

Some manufacturers deploy hybrid palletizing solutions, combining the speed of conventional systems with the versatility of robotics. Modular designs allow smaller businesses to scale up their automation investment gradually. Others integrate stretch wrapping and pallet labeling directly into the cell, reducing handling steps and streamlining logistics.

4. Key Benefits of Automated Palletizing

- Improved Efficiency & Throughput: Automated palletizers can run 24/7, eliminating bottlenecks and keeping production lines at optimal speed.

- Consistency & Product Quality: Every pallet is stacked with precision, reducing damage and ensuring uniformity for transport.

- Labor Savings & Worker Safety: Automation reduces repetitive strain injuries and allows staff to focus on higher-value tasks.

- Floor Space & Energy Optimization: Modern robotic systems often require less space and use 30% less energy compared to older equipment (Progressive Robotics, 2025).

5. ROI and Business Case for Automation

For food business owners, the ROI of palletizing automation is a key factor. Many manufacturers achieve payback in just 6–18 months, thanks to labor savings, reduced downtime, and improved throughput.

Beyond cost, consider total cost of ownership (TCO). Robotic palletizers require less maintenance and training than legacy systems, lowering long-term expenses. Buyers should also evaluate installation downtime for palletizer systems—many modular cells are designed to install within days, not weeks, minimizing disruption.

Small and mid-sized food businesses are increasingly investing in modular palletizing cells, which can scale as production grows. This approach makes automation accessible without requiring the upfront investment of a full-scale robotic system.

6. Technology That Powers Modern Palletizing

Gripper Systems

Mechanical, vacuum, and venturi grippers each serve different applications. Food-grade palletizing systems with hygienic design rely on stainless-steel grippers that withstand washdown environments.

Vision & Sensors

Vision systems detect product defects and ensure precise stacking. This prevents errors and improves load stability.

Software & Controls

Modern palletizers use software for pallet pattern programming, optimization, and traceability. At Velec, palletizing planning software allows operators to quickly reprogram for new SKUs, supporting agility in production.

7. Hygiene and Regulatory Compliance

Food safety is non-negotiable. Hygienic palletizer design ensures systems meet FSMA, EHEDG, and other global standards. Features include:

- Stainless steel frames and IP69K-rated components.

- Washdown-ready grippers and conveyors.

- Design that minimizes dirt traps and allergen cross-contamination.

According to Bin95 Engineering, hygienic palletizing systems must use non-toxic, corrosion-resistant, and non-absorbent materials to maintain compliance.

8. Integration with End-of-Line Packaging

Automated palletizers don’t work in isolation. They integrate with conveyors, case packers, elevators, and sorters to form a complete end-of-line solution.

Industry 4.0 systems connect palletizers to factory dashboards, providing real-time visibility into throughput, downtime, and maintenance. Velec’s turnkey systems include remote assistance and HMI controls for simplified operation.

9. Real-World Applications in Food Manufacturing

- Meat & Poultry: Velec’s IQF patties line integrates palletizing with quality control, washdown compliance, and operator-friendly HMI systems.

- Dairy & Beverage: Cartons and shrink-wrapped packs benefit from robotic palletizers that ensure stability in cold storage.

- Bakery & Grains: Lightweight products like cereal boxes require precision stacking to avoid crushing.

- Frozen & Ready Meals: Mixed-SKU palletizing ensures flexible distribution without extra handling.

10. Why Choose Velec Systems

For more than 70 years, Velec Systems has delivered turnkey, hygienic palletizing solutions for food manufacturers worldwide. Our systems integrate seamlessly with conveyors, loaders, and case packers—ensuring a smarter, safer, and more profitable end-of-line process.

With advanced features like vision QC, palletizing planning software, and remote support, we help food businesses scale efficiently and stay compliant.

13. Conclusion

Palletizing may be the final step in your production line, but it’s also one of the most important. As food manufacturers face rising labor costs, increasing compliance requirements, and pressure to deliver faster, palletizing solutions have become a strategic investment rather than a nice-to-have option. From conventional row-forming systems to advanced robotic palletizers, today’s technology enables businesses to boost throughput, protect workers, and ensure every pallet leaves the line stable and traceable.

The benefits go beyond efficiency. Automated palletizing reduces waste, improves product quality, and supports food safety through hygienic, washdown-ready designs. With ROI timelines often measured in months rather than years, automation pays for itself quickly while future-proofing your operations.

At Velec Systems, we’ve spent decades helping manufacturers integrate palletizing with conveyors, case packers, and smart factory systems to create seamless, compliant, and profitable workflows.

👉 If you’re ready to strengthen your end-of-line performance, contact Velec Systems today to explore a tailored palletizing solution for your food business.

What are palletizing solutions in food manufacturing?

Palletizing solutions in food manufacturing are automated systems that stack packaged products onto pallets for storage or shipment. They improve line efficiency, reduce manual labor, and ensure hygienic handling of food packaging. Modern palletizers also support traceability, food safety, and consistent load stability across product types.

What’s the difference between conventional and robotic palletizers?

The main difference lies in flexibility and automation.

- Robotic palletizers use articulated arms and custom grippers to handle multiple SKUs, shapes, and packaging formats, providing greater adaptability and precision.

- Conventional palletizers form layers using conveyors and row-forming systems—ideal for uniform cases.

How do palletizing systems improve food safety?

Food-grade palletizing systems enhance food safety through hygienic design—using stainless steel frames, sealed grippers, and IP69K-rated components. These systems withstand high-pressure washdowns and meet FSMA and EHEDG standards, preventing contamination while ensuring compliance and faster sanitation cycles.

What is the ROI of palletizing automation for food manufacturers?

Automated palletizing delivers a return on investment within 6–18 months for most food manufacturers. The savings come from reduced labor costs, shorter downtime, fewer injuries, and improved throughput, making automation one of the fastest-paying upgrades in food packaging operations.