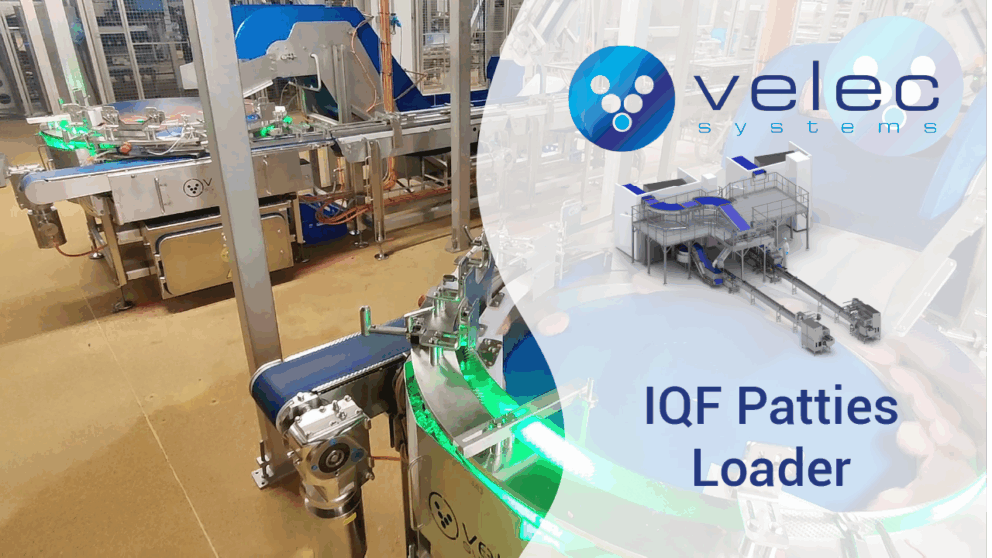

Velec’s IQF Burger Loading Solutions

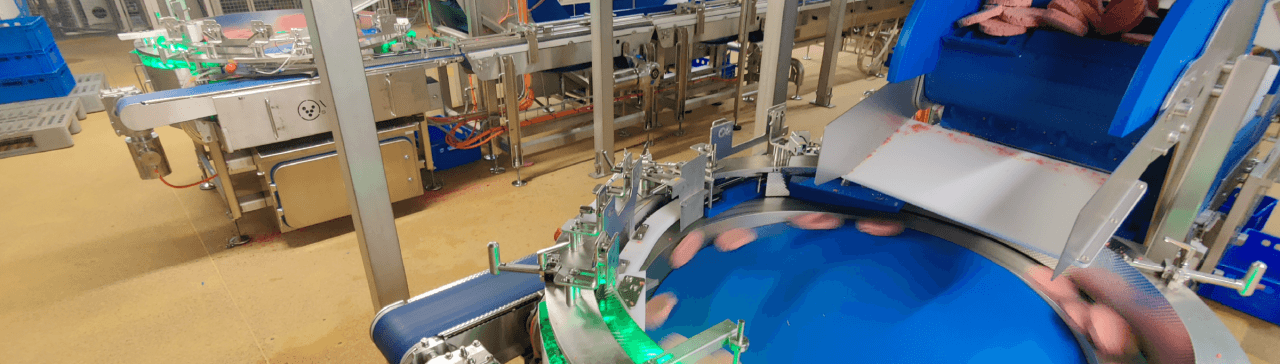

Ensure high-speed, continuous, and precise loading of your IQF burgers—preserving shape and texture every step of the way.

Engineered by our experts, our loaders are the most hygienic and flexible on the market, designed for seamless integration into your line.

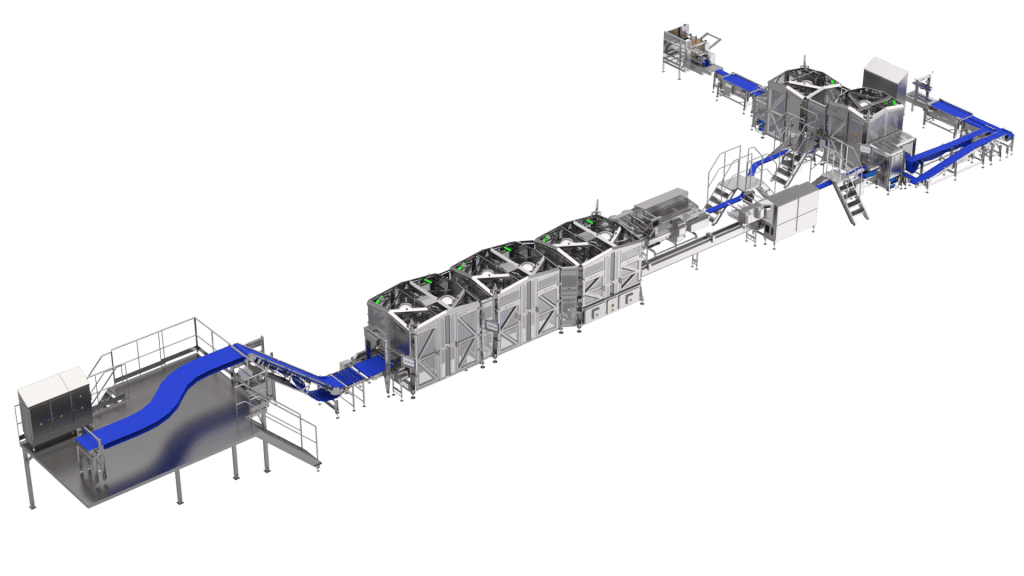

Choose the solution that fits your production:

• Mechanical Loader

• Robotic Loader

Handles up to 350 products per minute with unmatched consistency and efficiency.

| CENTRIFUGAL SOLUTION | ROBOTIC SOLUTION | |

| Shape | Round/Oblong/ Square/Rectangular | All shapes |

| Type | High pressure burger Low pressure burger Striated burger | High pressure burger Low pressure burger Striated burger |

| Dimension | Diameter: up to 150mm Length : up to 200mm Wide : up to 150mm Thickness : from 10mm to 40mm | All dimensions |

| Output | Up to: 250 pieces/min | Up to 80 pieces/min/robot |

| Option | Buffer Vrac | Buffer planaire |

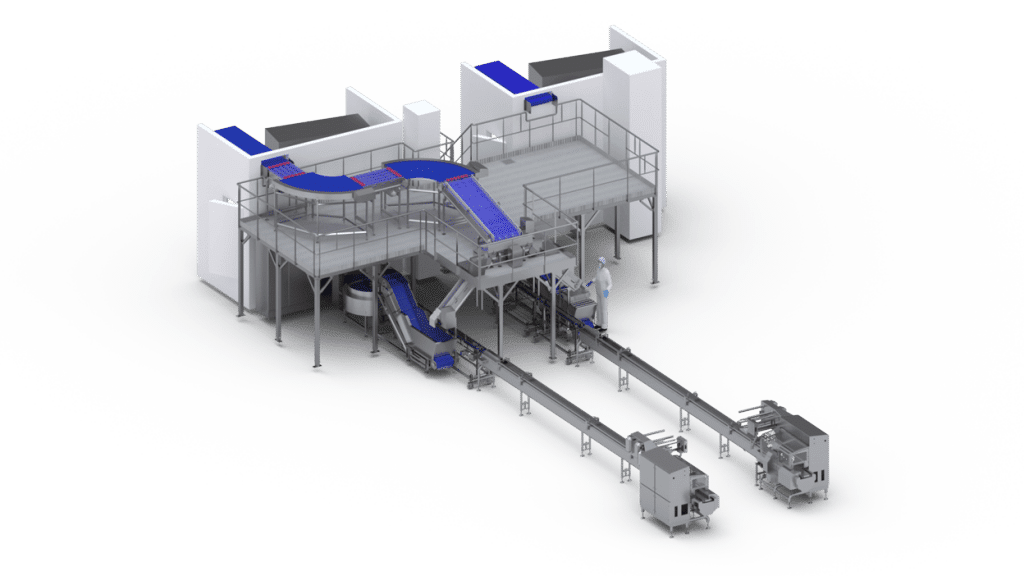

Optimize Your Production With Our Tailored Solution

To create the line that best fits your products, our experts have designed the most flexible and versatile solution.

Velec’s IQF Burger loader adapts to your products. It loads in all directions (parallel and perpendicular) and supports all packaging configurations (single or multi-layer, even or odd counts).

Maximize Your Process With Advanced Equipment and a Quality Control System

In addition, a quality control system rejects non-compliant products based on their shape, diameter, and length, ensuring you get perfect batches.

Going further, our solution provides statistics on the most frequent product defects, allowing you to fine-tune your quality plans.

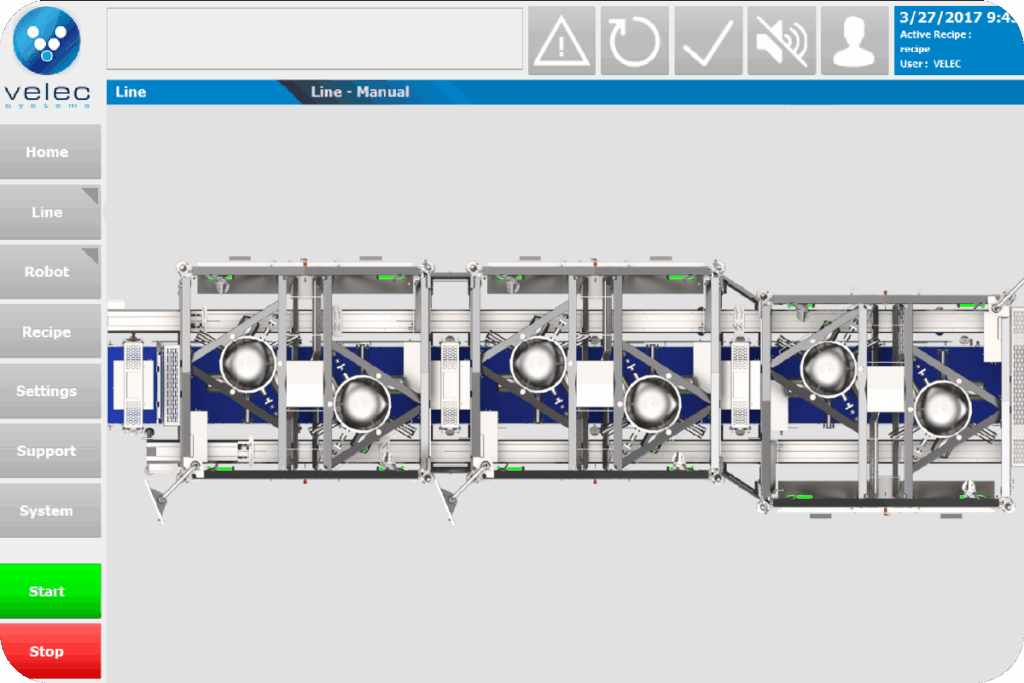

Boost Your Productivity With the Help of Our Intuitive and Versatile HMI

To optimize your production, our IQF Burger Loader preserves the shape and texture of your products. Perfectly adapted, it causes no waste or damage.

With its intuitive interface and user-friendly controls, even operators without technical experience can run the machine with ease.

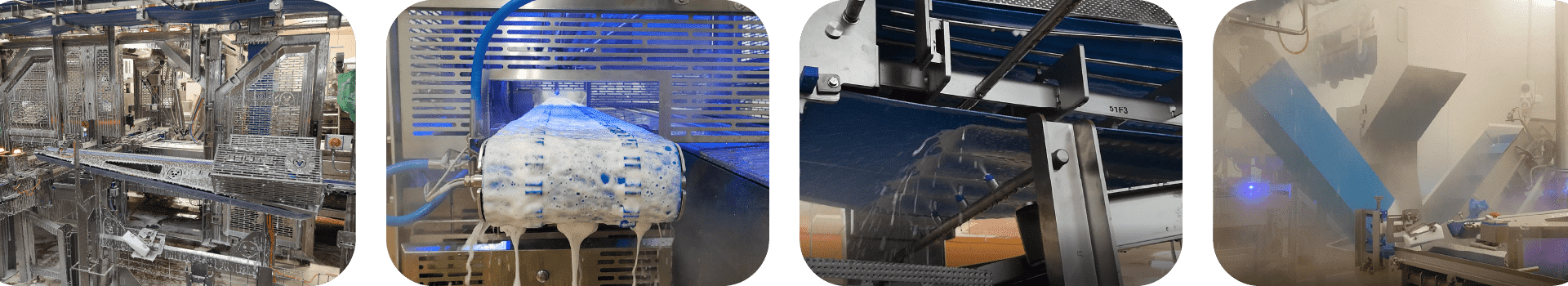

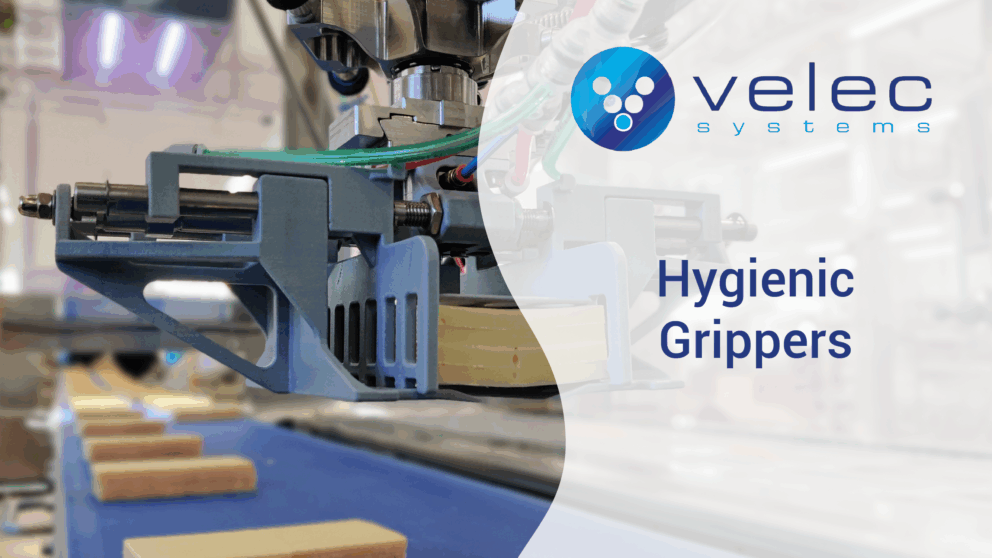

Increase your OEE Thanks to the Highest Level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

We prioritize the well-being of your customers, and food safety is at the core of our IQF Patties/Hamburger line. Our solution complies with stringent industry standards and incorporates cutting-edge technology to ensure the highest level of safety and hygiene. We leave no room for compromise when it comes to delivering safe, healthy, and delicious products to your customers.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).