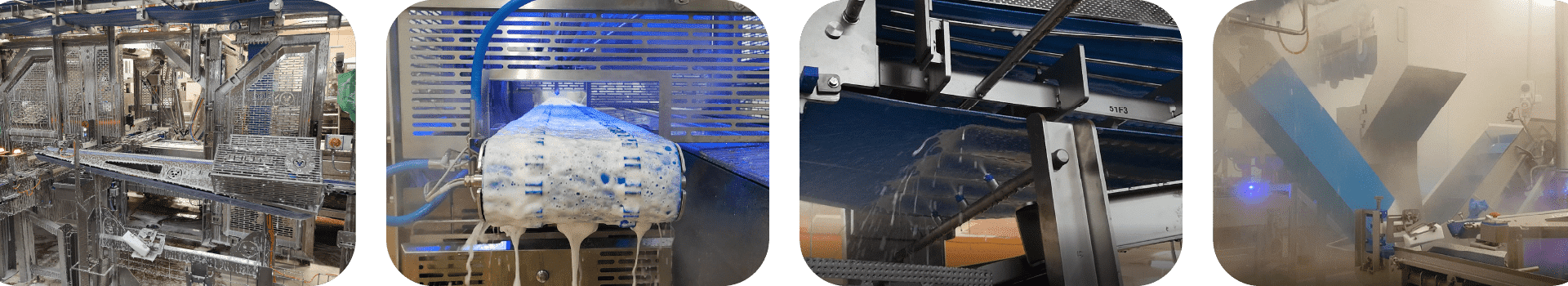

Cleaning In Place

In a cold and humid environment where bacteria can thrive, hygiene is not an option — it’s an absolute priority to ensure the food safety of your products and the trust of your consumers.

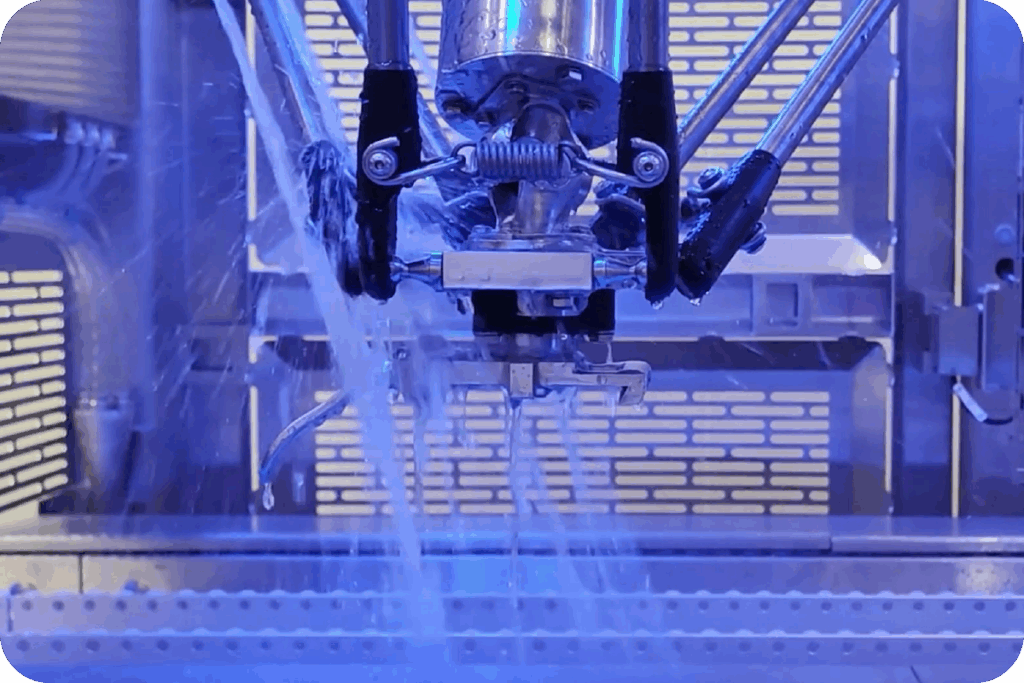

That’s why our CIP system (Cleaning In Place) is designed to support your teams in achieving optimal cleaning standards.

Reliable, intuitive, and efficient, it simplifies disassembly, speeds up cleaning, and significantly reduces downtime.

The result: a cleaner line, faster restarts — and increased productivity.

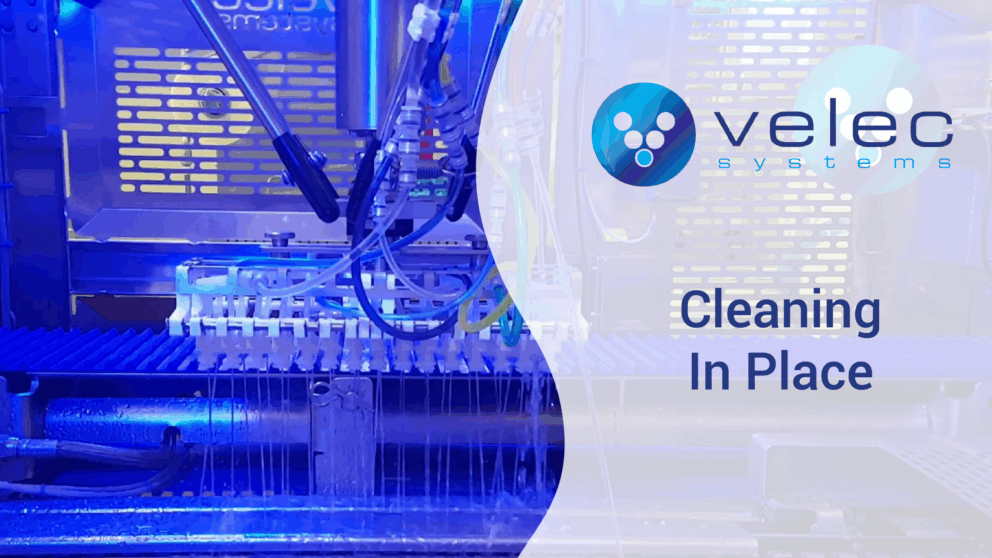

Automate Your Cleaning Process to Boost Efficiency

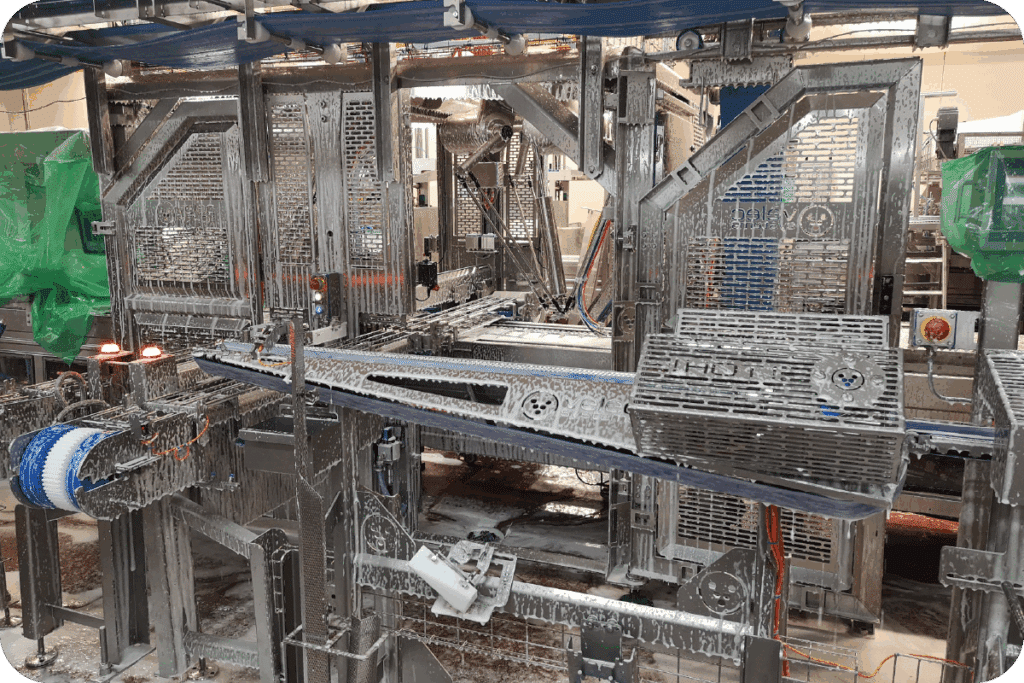

Designed to enhance your production performance, our CIP (Cleaning In Place) solution automates and simplifies your cleaning operations while ensuring consistent, repeatable results.

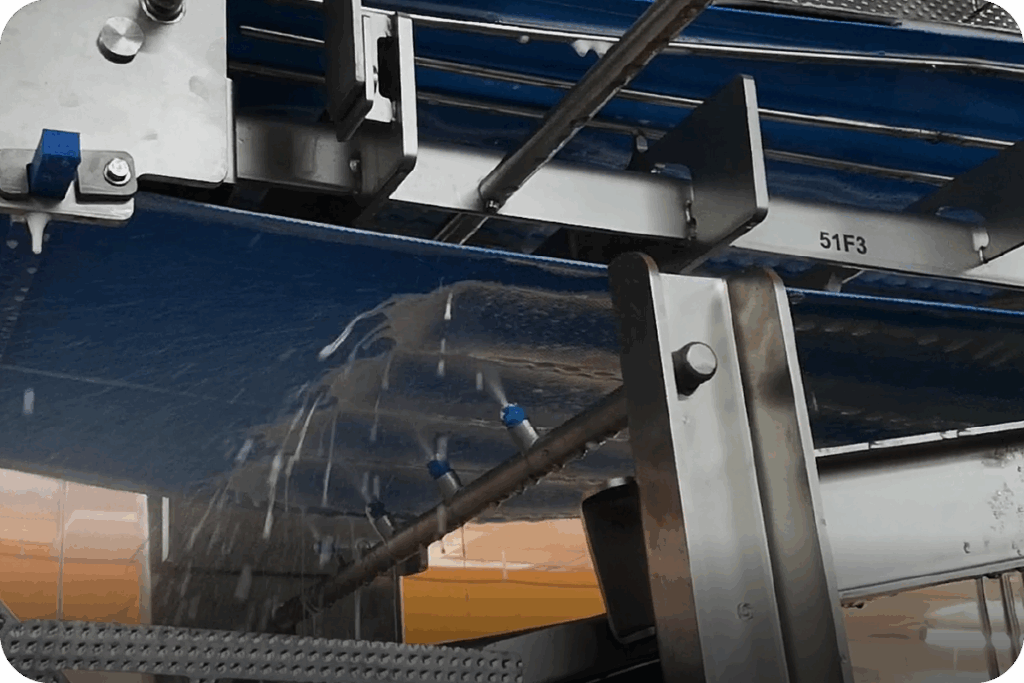

With easy connections to hot water, disinfectants, and cleaning agents, the system precisely controls application times for deep, effective cleaning of your equipment.

The result: less downtime, less effort for your teams, and impeccable hygiene.

Simplify Your Operators’ Work and Improve Their Daily Routine

To ease the workload of your teams and reduce human error, our experts have developed an intuitive, automated program designed to make cleaning operations simpler and more reliable.

With the CIP system, there’s no need to dismantle your lines — the cleaning solution is automatically sprayed across all surfaces, including hard-to-reach areas.

The result: less effort, greater safety, and real time savings for your teams.

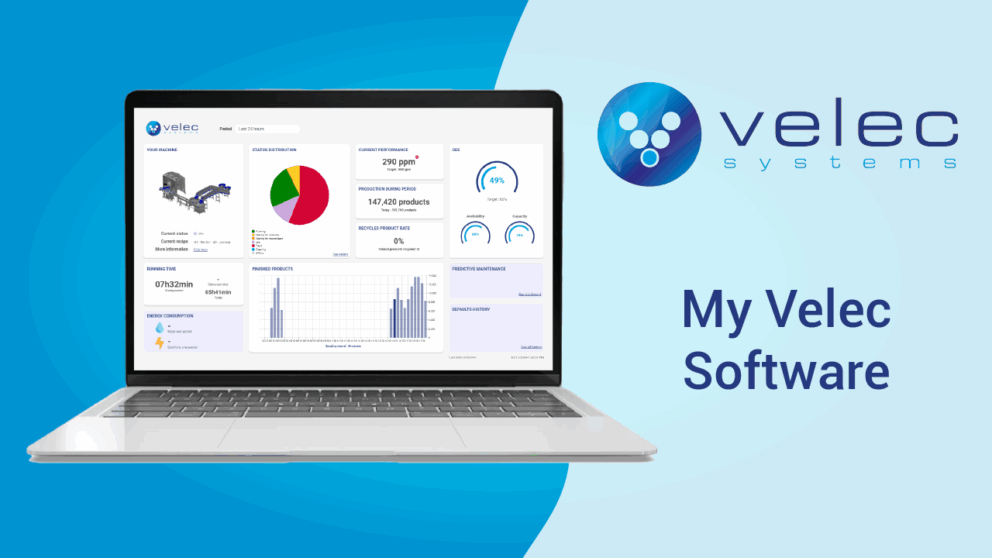

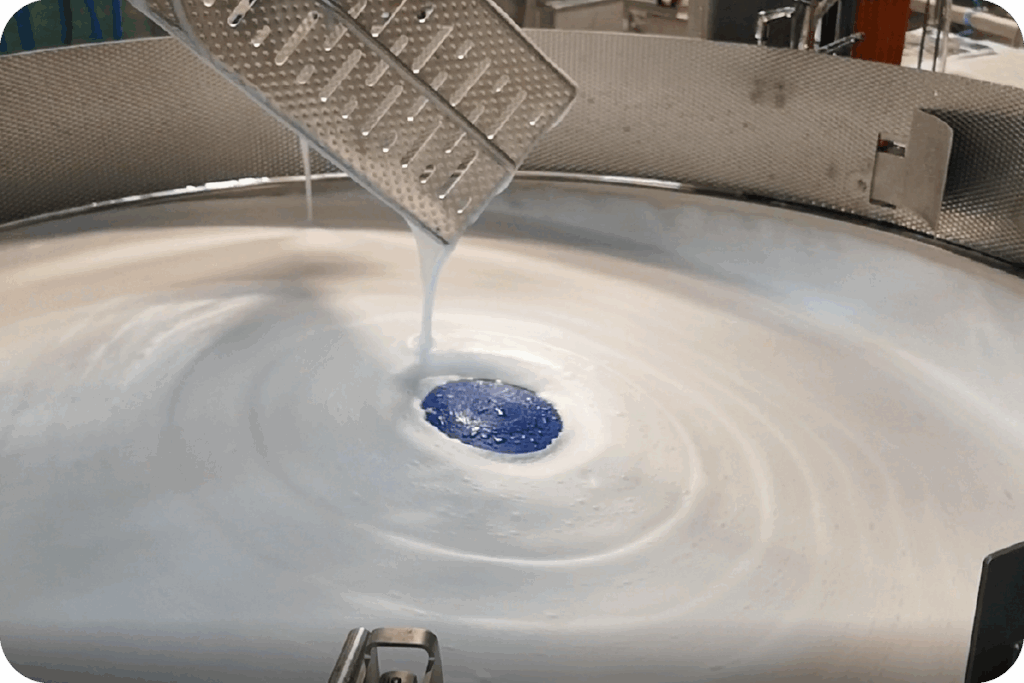

An Eco-Friendly Solution to Better Control Your Consumption

Managing water and chemical usage is a critical issue — not only for your operating costs, but also for the image you project to your customers.

With our CIP system, you stay in control: monitor your water and disinfectant consumption in real time while ensuring optimal cleaning performance.

Thanks to pre-programmed cycles and precisely controlled application times, you can reduce your water and cleaning product usage by up to 60%.

Less waste, more positive impact.

Increase Your OEE Thanks To the Highest Level of Hygiene in Your Plant

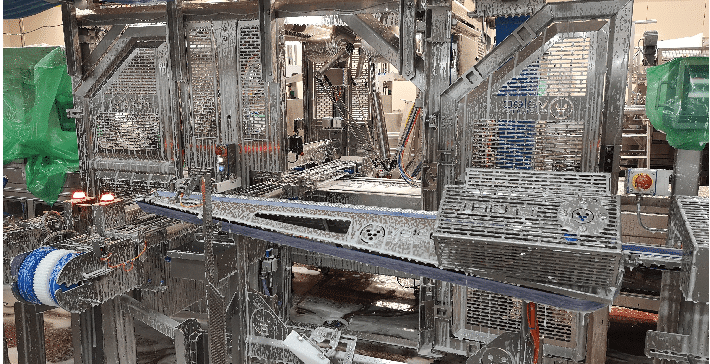

It’s has been designed to be as easy to clean as possible. It is dismantled without tools to simplify and maximize your cleaning operations. We are Compliant and exceed the recommendations of the EHEDG (European Hygienic Engineering and Design Group).

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors…) solution.

- Hygienic Design+ finish:

Microblasting (ra : 6,4).

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system.

NO WATER RETENTION

Open and incline structure to avoid retention area.

- No hollow tubing on all our equipment.

saving water and hygiene products

Up to 50% reduction in your water consumption and disinfection products thanks to CIP.

Possibility to set up your own cleaning sequence (hot water, foam, sanitizer).