The Future of Food Packaging with Vertical Loaders

Efficiency is everything in food packaging. From high-speed production lines to precision product handling, manufacturers need reliable solutions to keep up with demand. One of the biggest innovations in recent years is the vertical loader, a game-changing system designed to streamline packaging while maintaining product integrity and consistency.

Unlike traditional loading methods, vertical loaders optimize space, reduce labor costs, and improve food safety by minimizing human contact with products. Whether packaging frozen meals, dairy products, or ready-to-eat snacks, these automated systems help food manufacturers meet strict industry standards while increasing throughput.

This article explores the latest advancements in vertical loading systems, highlighting how they enhance efficiency in food packaging. We’ll break down the key benefits, from faster cycle times to seamless integration with existing production lines. You’ll also discover real-world applications, industry trends, and practical considerations for choosing the right vertical loader for your operation.

If you’re a food processing engineer or buyer looking to upgrade your packaging line, this guide will provide valuable insights to help you make an informed decision. Let’s dive into how vertical loaders are shaping the future of food packaging!

Quick Takeaways

- Vertical loaders improve packaging efficiency by reducing manual labor and increasing throughput.

- They save valuable floor space compared to horizontal loading systems.

- Automation enhances food safety by minimizing human contact and contamination risks.

- Modern systems use AI and sensors for real-time monitoring, precision, and minimal product damage.

- Vertical loaders are versatile, handling everything from snacks and dairy to frozen meals and ready-to-eat foods.

- They integrate seamlessly with existing equipment like thermoformers, baggers, and cartoners.

- Future trends include predictive maintenance and Industry 4.0 integration for smarter operations.

- Ideal for manufacturers looking to streamline operations, meet hygiene standards, and reduce long-term costs.

Understanding Vertical Loading Systems

What Is a Vertical Loader?

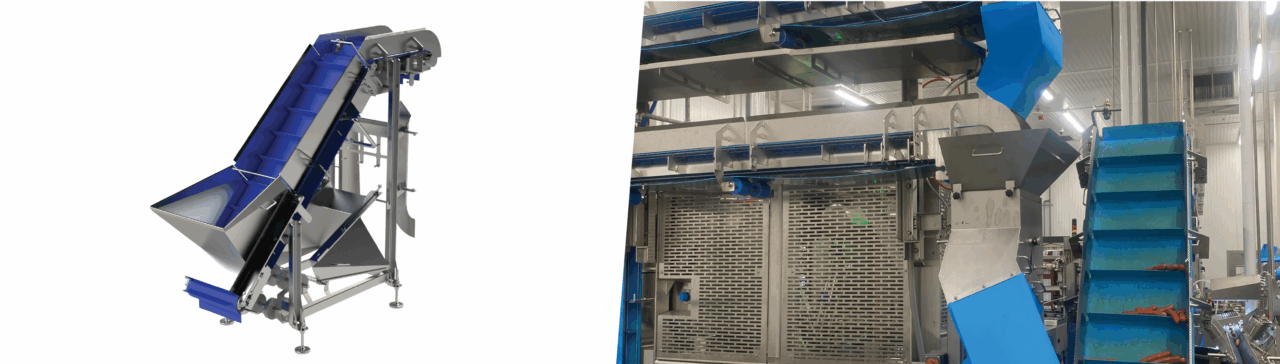

A vertical loader is an automated machine that loads food products into packaging from above. It uses gravity-assisted placement, conveyors, and robotic arms to ensure precise, efficient, and hygienic packaging. These machines help improve production speed while minimizing product damage.

How Vertical Loaders Differ from Other Packaging Systems

Unlike horizontal loaders, which insert products from the side, vertical loading equipment deposits items from above. This approach saves floor space, reduces product damage, and increases speed, making it a better fit for high-volume food packaging operations.

Key Components of a Vertical Loading System

- Conveyors: Transport products to the loading area.

- Elevators: Lift products to the appropriate height for loading.

- Robotic Arms or Loading Mechanisms: Precisely place products into packaging.

- Sensors and Cameras: Ensure products are correctly positioned and properly packaged.

For example, Velec Systems offers a vertical bagger loader that combines advanced sensor technology with a hygienic design, capable of counting and loading up to 5,000 products per minute without causing damage.

The Evolution of Vertical Loading Technology

Early Vertical Loaders: Manual and Semi-Automatic Solutions

Older packaging systems relied heavily on manual labor or semi-automated processes, which often led to inconsistencies and inefficiencies.

Modern Innovations in Vertical Loading Systems

Today’s vertical loaders incorporate AI-driven adjustments, real-time monitoring, and automated error detection to optimize efficiency.

Future Trends in Vertical Loading Systems

- Integration with Industry 4.0 for data-driven performance.

- Predictive maintenance to prevent downtime.

- AI-powered automation for precise product handling.

Benefits of Using Vertical Loaders in Food Packaging

Increased Production Efficiency

Vertical loading systems significantly boost throughput, allowing manufacturers to package products faster with minimal errors.

Improved Product Safety and Hygiene

By reducing human contact, vertical bagger loaders help maintain food safety and meet industry regulations like HACCP and GMP.

Reduced Labor Costs and Human Error

Automation reduces reliance on manual labor, leading to lower operational costs and fewer packaging errors.

Maximized Packaging Line Space Efficiency

Compared to horizontal loading solutions, vertical loaders require less floor space while maintaining high performance.

Applications of Vertical Loaders in the Food Industry

Snack Foods and Baked Goods

Efficiently loads chips, cookies, and pastries into packaging.

Frozen and Refrigerated Products

Handles frozen meats, vegetables, and ready meals with ease.

Dairy and Beverage Packaging

Optimizes packaging for yogurt, cheese, and milk products.

Ready-to-Eat and Meal Prep Packaging

Ensures precise portioning for pre-portioned meals and salads.

FAQs: Common Questions About Vertical Loaders

1. What is a vertical loader, and how does it work?

A vertical loader automates food product placement into packaging from above, using conveyors, gravity-fed systems, and robotic arms for efficiency and precision.

2. How do vertical loaders improve efficiency?

They reduce manual labor, increase throughput, and optimize space by minimizing product handling time.

3. Can vertical loaders handle different food products?

Yes, they are adaptable for snacks, dairy, frozen foods, and ready meals, among other applications.

4. How do vertical loaders contribute to food safety?

By reducing human contact, they lower contamination risks and comply with food safety regulations.

5. Are vertical loaders cost-effective?

While the initial investment can be high, the long-term savings on labor and efficiency make them a cost-effective solution.

Conclusion: The Future of Food Packaging with Vertical Loaders

As food packaging demands continue to evolve, vertical loaders have emerged as a critical innovation for manufacturers looking to enhance efficiency, reduce costs, and improve product integrity.

From snack foods to frozen meals, dairy products, and ready-to-eat meals, vertical loaders offer versatility across multiple industries. Their ability to seamlessly integrate with existing packaging lines—such as thermoformers, vertical baggers, and cartoners—ensures smooth operations while reducing downtime and labor costs.

If you’re looking to upgrade your packaging line with a high-speed, precise, and cost-effective solution, a vertical loader could be the key to staying ahead in the industry. Explore the latest innovations in vertical loading technology and see how it can transform your operations. Visit Velec Systems to learn more or consult with an expert to find the best solution for your production needs.

References

Velec Systems. “Vertical Bagger Loader.” https://www.velecsystems.com/en/solution_technique/loading/vertical-loading/

Sealed Air Corporation. “Vertical Form-Fill-Seal Equipment.” https://www.sealedair.com

Schneider Packaging Equipment Co., Inc. “Vertical Bottom Loading Case Packer Solution | Everest.” https://www.schneiderequip.com

Rennco, LLC. “Vertical Cup Counter/Loader VCCL.” https://www.rennco.com