Every year, food manufacturers lose millions in wasted ingredients—often from something as simple as inconsistent portioning. That’s why more processors are turning to volumetric dosing. By measuring ingredients based on volume rather than weight, volumetric dosing systems give food processors the speed and efficiency needed to keep production moving without compromising on quality.

But is volumetric dosing the right fit for your business? In this article, we’ll explore how volumetric dosing works, why it has become a go-to choice for many food manufacturers, and how it compares to gravimetric dosing. We’ll look at its benefits—like reduced waste, lower costs, and easier integration—as well as the limitations you need to consider. Along the way, we’ll share real-world applications, industry compliance insights, and future trends like IoT-enabled systems and hybrid solutions.

By the end, you’ll have a clear understanding of how volumetric dosing can help your food business achieve precision, efficiency, and growth.

Quick Takeaways: Volumetric Dosing in Food Processing

- Volumetric dosing measures by volume, not weight, offering speed and simplicity.

- Cost-effective and scalable, ideal for both small and large food processors.

- Delivers ±3–5% accuracy, suitable for most high-throughput lines.

- Supports FSMA, HACCP, and EHEDG compliance with CIP and hygienic designs.

- Hybrid systems balance speed and accuracy for critical applications.

- Applications span bakery, meat, dairy, sauces, and ready meals.

- Helps businesses reduce waste, improve ROI, and meet sustainability goals.

1. Understanding Volumetric Dosing

1.1 What Is Volumetric Dosing?

Volumetric dosing is the process of measuring and dispensing a fixed volume of product, rather than its weight. Equipment such as screw feeders, pumps, and hoppers deliver predictable quantities of powders, liquids, or pastes. This makes it a faster and simpler alternative to weighing systems for many everyday applications.

1.2 Core Principles of Operation

- Screw feeders: rotate at a fixed speed to move powders.

- Progressive cavity pumps: displace a set amount of liquid or paste per cycle.

- Vibratory feeders and rotary valves: use controlled motion for consistent flow.

Each movement equals a consistent volume of product, ensuring repeatability and speed.

1.3 Common Applications

- Powders: flour, spices, sugar.

- Granules: rice, pasta, grains.

- Liquids/pastes: sauces, nut butters, dairy products.

Volumetric dosing isn’t just about moving ingredients; it’s about enabling predictability in operations—less waste, fewer bottlenecks, and more reliable quality.

2. Why Food Processors Choose Volumetric Dosing

2.1 Speed and Throughput

High-speed bakeries and snack plants rely on volumetric dosing to keep pace with demand. A screw feeder can deliver flour at a predictable rate without weighing every batch, ensuring throughput doesn’t slow down (Palamatic Process).

2.2 Cost and Simplicity

Volumetric systems are generally more cost-effective and easier to maintain than gravimetric systems. Training requirements are lower, making them ideal for teams managing multiple product lines.

2.3 Compact Design and Integration

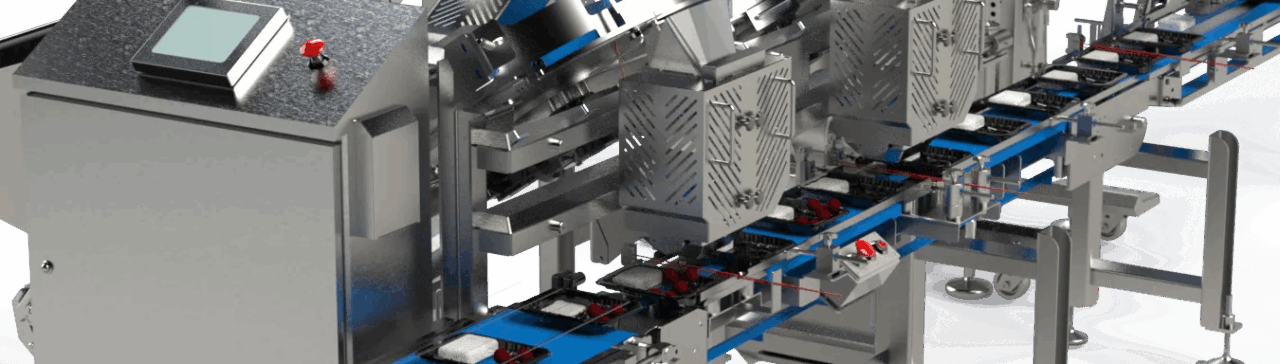

Modern designs are compact and modular, fitting seamlessly into existing lines. For example, Velec Systems’ Multi-Fill volumetric dosing solutions handle everything from rice to diced fruits with hygienic stainless-steel construction (Velec Systems Volumetric Dosing).

3. Accuracy, ROI, and Compliance

3.1 Accuracy

Volumetric dosing typically achieves ±3–5% accuracy, compared to gravimetric’s ±1% (Motan Group). For most applications—such as pasta or rice in ready-meal trays—this is more than sufficient.

3.2 ROI

Overfills add up. A bakery running 10,000 units per day could lose thousands annually in wasted flour. Volumetric dosing balances predictable output with cost savings, making ROI more attractive for high-throughput operations.

3.3 Compliance and Food Safety

Volumetric dosing equipment is built with food safety regulations in mind. Features like clean-in-place (CIP), stainless-steel construction, and sloped surfaces ensure compliance with FSMA, HACCP, EHEDG, and FDA standards (Velec Systems Hygienic Design).

4. Technical Considerations for Implementation

4.1 Material Characteristics

Flowability, density, and moisture impact dosing performance. Sticky powders like cocoa may need agitators to avoid clumping (Van Beek).

4.2 Calibration

Volumetric systems need recalibration when switching materials, since density fluctuations affect volume-to-weight ratios (Motan Group).

4.3 Cleaning and Hygiene

Hygienic design is critical. Velec equipment supports CIP systems that allow faster, safer cleaning—reducing downtime between production runs.

5. Volumetric vs. Gravimetric: Choosing the Right Fit

- Volumetric dosing: cost-effective, faster, simpler.

- Gravimetric dosing: more precise, adapts to density changes automatically (DEMIC Datentechnik).

5.1 Hybrid Approaches

Many modern plants combine the two: volumetric systems pre-feed product quickly, and gravimetric scales verify accuracy. This delivers speed and precision together.

6. Customization and Scalability

6.1 Tailored Solutions

- Liquids: progressive cavity pumps for sauces, yogurt.

- Sticky foods: agitator-equipped feeders for cheese or chocolate.

- Mixed meals: modular fillers for pasta plus sauce.

6.2 Scalability

Velec’s modular dosing units can grow with your business, from pilot lines to full-scale factories.

6.3 Integration

Systems integrate seamlessly with tray sealers, thermoformers, and sausage loaders, maximizing end-of-line efficiency.

7. Case Scenarios: Volumetric Dosing in Action

- Bakery: flour and sugar dosing in continuous lines.

- Meat & Ready Meals: portioning rice and sauces into trays.

- Dairy & Confectionery: filling yogurt cups or chocolate pralines.

- Sauces: pulsation-free dosing of ketchup, curry, or cream sauces.

Each example underscores how volumetric dosing systems for food production are versatile enough to handle both dry and liquid ingredients without slowing down throughput.

8. Reducing Waste and Improving Sustainability

- Ingredient savings: consistent portions reduce overfill, cutting ingredient waste by up to 10–15% in high-volume plants.

- Resource efficiency: compact design reduces power usage.

- Sustainability: aligns with corporate goals to minimize food waste.

Buyers increasingly weigh sustainability alongside efficiency. By choosing volumetric dosing, processors can demonstrate progress toward waste reduction and environmental responsibility, building trust with retailers and consumers alike.

9. Future Trends in Volumetric Dosing

- Smart IoT-enabled volumetric dosing systems that self-adjust in real time.

- Data integration for traceability, linking batch records to dosing output.

- Hygienic innovations: faster CIP and reduced water usage.

These advances mean food processors won’t just be choosing equipment—they’ll be investing in connected, intelligent systems that improve quality assurance and compliance.

Conclusion

In food processing, the ability to deliver consistent quality at scale is what separates thriving businesses from those struggling to keep pace. Volumetric dosing offers a proven way to achieve this balance, combining speed and simplicity with the precision necessary for most everyday applications.

We’ve seen how volumetric dosing stands out for its cost-effectiveness, scalability, and ease of integration into existing lines. While gravimetric systems provide higher accuracy, volumetric dosing often delivers the best overall value when speed and efficiency are top priorities. Hybrid solutions now make it possible to enjoy both, combining rapid pre-dosing with final weight checks to minimize waste and maximize compliance.

For business owners and buyers, the takeaway is clear: investing in the right dosing system is not just about equipment—it’s about improving ROI, safeguarding compliance, and building customer trust.

What does volumetric dosing mean in food processing?

Volumetric dosing measures and dispenses ingredients by volume instead of weight. Using pumps or screw feeders, it delivers consistent portions of powders or liquids for each cycle, ensuring uniform product quality without requiring complex weighing systems.

How accurate is volumetric dosing compared to gravimetric dosing systems?

Volumetric dosing offers good consistency—typically within ±3–5%. Gravimetric systems, which measure by weight, can achieve up to ±1% accuracy. The choice depends on whether speed or precision is your production priority.

What are the main advantages of using volumetric dosing in food production?

Key benefits include:

- Fast dispensing for high-volume production

- Lower equipment and maintenance costs

- Easy integration into existing lines

Can volumetric dosing systems handle both powders and liquids?

Yes. Volumetric feeders and pumps can dose a wide range of materials—from dry ingredients like flour, sugar, and spices to viscous products such as sauces, creams, and nut butters—using specialized augers or pump heads for each material type.

How do you calibrate a volumetric screw feeder for accurate dosing?

- Run the feeder for a timed interval.

- Collect and weigh the discharged material.

- Compare the actual output to your target dose. Regular calibration ensures consistent dosing accuracy.

- Adjust screw speed or pitch until the output matches your setpoint.

Is volumetric dosing equipment compliant with FSMA and HACCP standards?

Yes. Modern volumetric dosing systems are built from food-grade stainless steel and feature hygienic seals, CIP (clean-in-place) capability, and tool-free disassembly—ensuring compliance with both FSMA and HACCP food safety requirements.

Which food industries use volumetric dosing systems the most?

- Bakeries: for flour, sugar, and mixes

- Dairy: for yogurt, cheese, and powders

- Sauces and dressings: for liquids and emulsions

- Snacks and ready meals: for seasonings and portions

How does volumetric dosing help reduce food waste in production lines?

Volumetric dosing minimizes overfill and product variation, cutting ingredient waste by up to 15%. By dispensing exact portions each time, it helps reduce giveaway, optimize raw material use, and improve sustainability across food packaging lines.

References

Hygienic Design — CIP engineering and compliance with EHEDG, FDA, USDA. (Velec Systems)