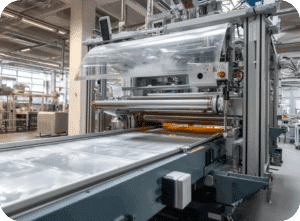

In today’s competitive food manufacturing landscape, even a few minutes of unplanned downtime can disrupt production, damage customer trust, and shrink margins. That’s why thermoformers—essential machines in many automated food packaging lines—must operate with precision and reliability. But what happens when things go wrong?

Whether you’re a CEO overseeing high-volume packaging operations or a buyer evaluating equipment investments, understanding how to quickly diagnose and resolve common thermoformer issues is essential. From misaligned film feeds to inconsistent forming and sealing problems, small technical hiccups can lead to big inefficiencies, wasted product, or even failed inspections.

This guide walks you through the five most common thermoformer issues found in food packaging lines—and more importantly, how to fix them. You’ll learn how to recognize early warning signs, implement preventive maintenance, and make smarter decisions about tooling, temperature control, and vacuum systems. We’ll also explore how smart automation and hygienic design features can reduce downtime and improve your bottom line.

Quick Takeaways

- Thermoformers are vital to high-efficiency food packaging lines, but even minor malfunctions can lead to costly downtime and compromised product safety.

- The five most common issues—uneven forming, poor seals, film feed errors, vacuum/pressure failures, and misaligned cutting—are preventable with regular calibration and maintenance.

- Precision in heating, forming, and sealing is critical to meeting food safety standards and minimizing packaging defects.

- Long-tail problems often stem from small oversights, such as dirty sealing surfaces, worn rollers, or improperly tensioned film.

- Preventive maintenance schedules and operator training are your frontline defense against unexpected line stoppages and wasted materials.

- Advanced features like smart sensors, servo-driven cutting, and auto-centering film guides can dramatically improve uptime and reduce manual adjustments.

- Partnering with equipment providers like Velec Systems ensures you benefit from hygienic design, modular tooling, and automation-ready platforms.

Common Issues and How to Fix Them

1. Inconsistent Forming Depths

This issue typically results from uneven heating or misaligned molds. Inadequate temperature control can cause trays to form too shallow or deep, compromising product fit and seal. Use multi-zone PID controllers to stabilize heating and ensure your forming station has proper vacuum levels. Velec’s modular tooling designs also minimize forming variation by maintaining better mold alignment across batches.

2. Poor Seal Integrity

Poor seals are one of the top culprits behind failed inspections. These often stem from contaminated seal surfaces, uneven pressure, or worn sealing elements. Implementing CIP (clean-in-place) systems and regularly inspecting heat-seal tooling can prevent this.

3. Film Tracking or Feeding Errors

Misfeeds occur when the film drifts out of alignment due to worn tension rollers, skewed guide tracks, or debris in feed zones. Solutions include adding auto-centering guides, regularly cleaning rollers, and using edge-sensing technology. Smart film indexing systems can reduce errors at startup.

4. Vacuum or Pressure Failures

When your forming station lacks adequate vacuum pull or pressure, trays won’t mold cleanly—leading to costly rejects. Causes may include clogged vacuum lines, aging pumps, or sensor faults. Install pressure sensors and routinely inspect vacuum lines to catch degradation early.

5. Inconsistent Cutting or Misalignment

Poor trim quality or offset cutting happens when blades dull or lose sync with the forming cycle. Servo-driven cutting units outperform pneumatic systems here, allowing for greater speed and accuracy. Velec integrates these into its equipment to boost output without sacrificing consistency.

Preventive Maintenance Strategies

Effective maintenance plans should include daily inspections, weekly part checks, and monthly diagnostics. Use structured checklists and train operators to log anomalies. Smart systems alert teams to pre-failure conditions, dramatically reducing emergency stops. Think of preventive care as operational insurance—it costs less than recovery.

Conclusion

In today’s fast-paced food packaging environment, equipment reliability is more than a technical concern—it’s a business imperative. Thermoformers play a central role in ensuring product safety, visual appeal, and throughput. Yet, when even minor issues—like uneven forming, poor seals, or vacuum failures—go unchecked, the consequences can include product recalls, wasted inventory, and lost revenue.

The good news? Most thermoformer problems are highly preventable. By understanding the five most common issues and implementing targeted fixes—such as calibrating heating zones, upgrading to servo-driven cutters, or adopting auto-centering film systems—you can turn troubleshooting from a reactive task into a proactive strategy. Regular maintenance and training, combined with smart automation, extend equipment life and safeguard production integrity.

At Velec Systems, we specialize in designing hygienic, modular solutions tailored to modern food packaging demands. Our machines are engineered not only to minimize downtime but to simplify diagnostics and improve line efficiency from day one.

Contact us today to see how we can help you get your food factory producing at its best!

Frequently Asked Questions (FAQs)

1. What causes poor seal integrity in food thermoforming machines?

Poor seal integrity often results from contaminated sealing surfaces, worn tooling, or improper temperature settings. To fix this, implement a clean-in-place (CIP) system and regularly inspect seal bars.

2. How can I reduce downtime in my thermoformer packaging line?

Use a thermoformer maintenance checklist, smart sensors for diagnostics, and train operators to recognize early warning signs. Proactive upkeep is essential.

3. Why is my thermoformer not forming trays uniformly?

This issue often stems from uneven heating or fluctuating vacuum pressure. Check your heating zones and vacuum calibration for consistency.

4. What’s the best way to fix film tracking issues on a thermoformer?

Use auto-centering guides, replace worn rollers, and monitor the film indexing system closely.

5. How often should I perform preventive maintenance on my thermoformer?

Daily visual checks, weekly cleaning, and monthly diagnostics are recommended. Structured maintenance ensures consistent performance.

6. What are the benefits of servo-driven cutting systems?

Servo-driven cutting systems improve accuracy, reduce alignment issues, and perform better at high speeds than pneumatic systems.

7. Can smart sensors really help diagnose thermoformer problems?

Yes. Smart sensor integration enables real-time monitoring of heat, pressure, and vacuum parameters, improving uptime and early detection.

8. How do I choose the right thermoformer for my food packaging line?

Evaluate hygienic design, throughput capacity, automation features, and OEM support. Partner with providers who offer tailored solutions and technical expertise.

References

- RezPack. (2024). Thermoforming machine troubleshooting and solutions. rezpack.com

- MaintWiz. (n.d.). Daily Maintenance Checklists for Packaging Equipment. maintwiz.com

- BMG. (n.d.). Introduction to Thermoforming: A Comprehensive Guide. onebmg.com

- Plastics Technology. (n.d.). Maintain the Life of Your Thermoformer. ptonline.com

- Advanced Plastiform. (n.d.). Impact of Thermoforming on the Food Industry. advancedplastiform.com

- Skjöldebrand, C. (2013). Food-Processing Equipment. In C.G.J. Baker (Ed.), Handbook of Food Factory Design. Springer.

- Velec Systems. (n.d.). Thermoformer Machines in Sausage Packaging. velecsystems.com

- Velec Systems. (n.d.). MyVelec Software. velecsystems.com

- Velec Systems. (n.d.). Clean-In-Place Equipment in Meat Packaging Lines. velecsystems.com