Nowadays, sustainability has become an increasingly important focus across industries, and the food industry is no exception. To ensure the production of safe and high-quality products, manufacturers are adopting sustainable practices throughout their operations. One crucial aspect of this sustainable approach is hygienic design. This paradigm encompasses the use of materials, equipment, and processes that promote cleanliness, prevent cross-contamination, and enhance food safety.

In this article, we will explore the numerous benefits of hygienic design in the food industry, demonstrating how it contributes to a sustainable future.

1 – Improved Food Safety for Food Waste Reduction

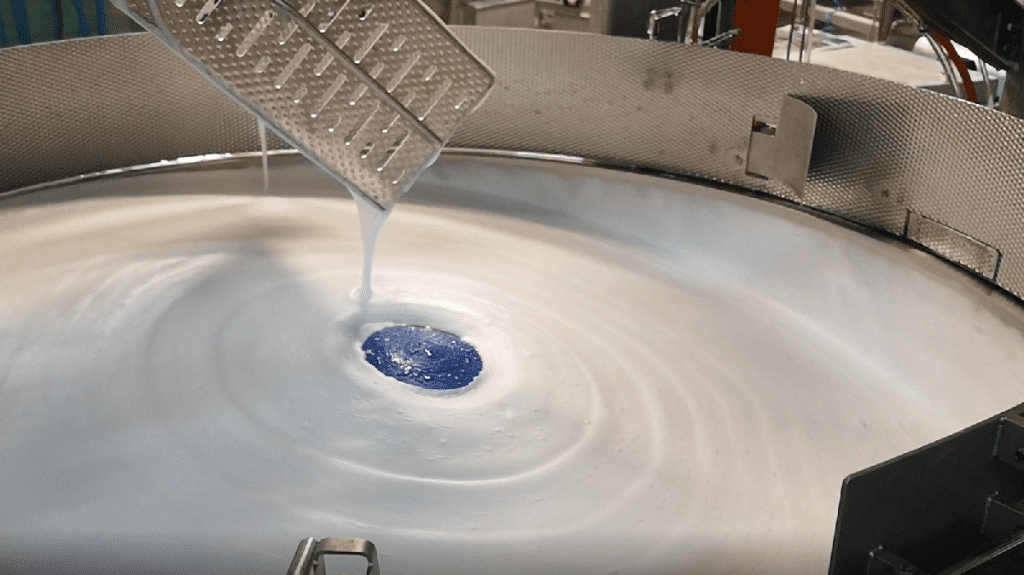

Food safety is paramount in the food industry. Implementing hygienic design principles helps minimize the risk of foodborne illnesses by reducing contamination. Equipment and facilities designed with smooth surfaces, rounded corners, and easily cleanable materials prevent the accumulation of water, along with bacteria, and other harmful pathogens. This, in turn, improves food safety standards and reduces the likelihood of product recalls, protecting both consumers and the reputation of food businesses. By doing so, it contributes to food waste reduction.

2 – Enhanced Cleanliness and Water-Efficiency

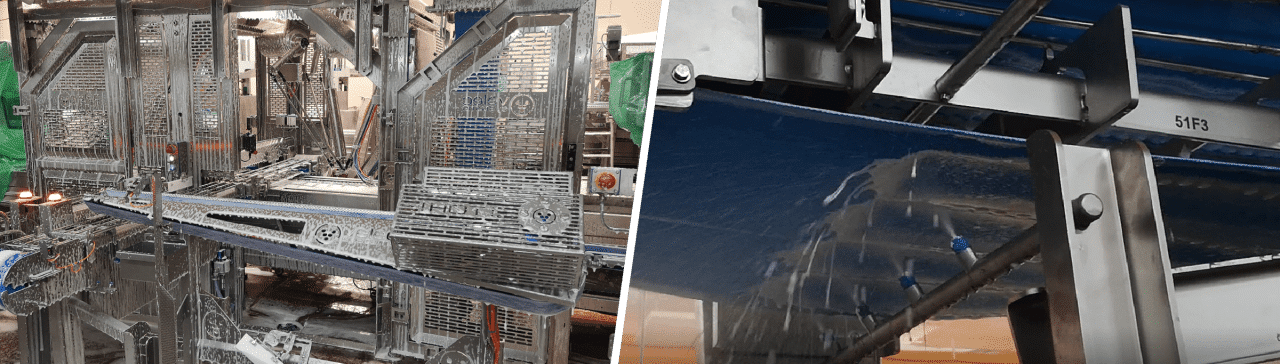

Hygienic design facilitates efficient and effective cleaning practices. Equipment and machinery that are easy to disassemble, clean, and sanitize enable thorough cleaning processes, eliminating potential microbial hazards.

Additionally, smooth surfaces with a 0.4-to-0.8-average-roughness (Ra) prevent the accumulation of residue or particles, making cleaning faster and more efficient. The design of the machines is crucial: every details need to be thought to avoid cleaning retention.

This not only saves time and resources but also reduces the consumption of water, energy, and cleaning agents, aligning with sustainable operational practices.

3 – Extended Equipment Lifespan

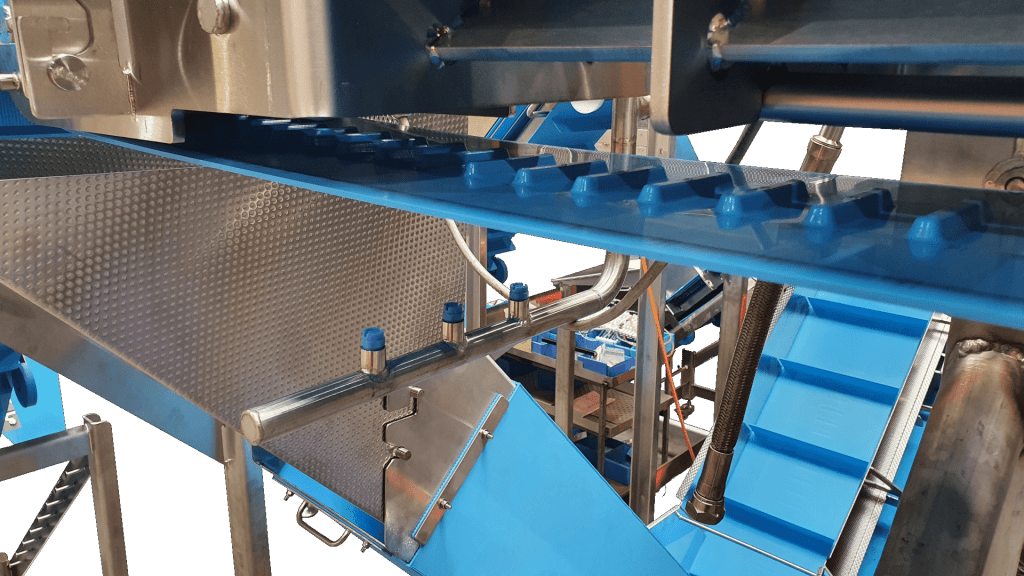

Investing in hygienic design can lead to significant cost savings over time. By choosing equipment and facilities designed for cleanliness and durability, food businesses can reduce the frequency of repairs, replacements, and downtime. Hygienic design features such as corrosion-resistant materials, proper drainage systems, and effective seals protect machinery from wear and tear caused by cleaning agents and exposure to moisture. By extending the lifespan of equipment, businesses reduce waste, they minimize environmental impact, and optimize their operational efficiency.

4 – Getting Ahead of Regulations and Standards

Regulatory bodies and industry organizations continually update and enforce stringent guidelines for food safety and hygiene.

By implementing hygienic design practices we have become reel experts on the matter. We have built our hygienic design expertise by listening to our customers and exceeding the EHEDG and the Food Safety Culture’s recommandations.

By incorporating design features that align and exceed industry standards, such as the use of food-grade materials, hygienic finishes, you demonstrate your commitment to upholding the highest standards of food safety. Compliance not only ensures the well-being of consumers but also fosters trust and credibility within the industry.

5 – Streamlined Maintenance and Inspections

Efficient maintenance and regular inspections are vital for identifying potential risks, ensuring compliance, and minimizing downtime. Hygienic design makes maintenance tasks easier and less time-consuming, reducing operational disruptions. Equipment with fewer parts, clear accessibility, and standardized connections simplifies routine inspections and facilitates proactive maintenance. This proactive approach prevents unexpected breakdowns, maximizes uptime, and promotes a sustainable production environment.

As the food industry embraces sustainability, adopting hygienic design principles has become a necessity. The benefits of hygienic design in the food industry are multifaceted, ranging from improved food safety and enhanced cleanliness to extended equipment lifespan and streamlined operations.

By investing in hygienic design, food businesses not only ensure the production of safe and high-quality products but also contribute to a sustainable future by reducing waste, preserving resources, and complying with regulations. Embracing hygienic design practices is a step toward creating a more resilient and responsible food industry that prioritizes the well-being of consumers and the planet.

However, designing the most cleanable machines is far from being an easy task. As Leonard Da Vinci said “Simplicity is the ultimate sophistication”. Over the years, our engineering team have developped a true expertise in that matter.

If you want to know more about our hygienic design solutions or if you need to implement one of them to safely load your products into your primary packing, feel free to reach out to our experts. They can evaluate the potential savings you could benefit from using our hygienic design lines.