Your products, process, and lines are unique. At Velec, our cutlery deposition solution is custom-made to adapt to your products and your operating constraints!

Simplify your operations with our cutlery depositor solutions

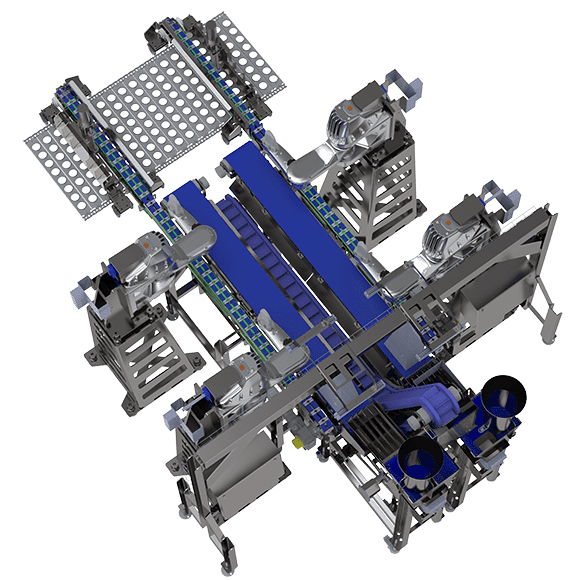

VELEC Systems has developed a high-speed cutlery distribution solution that can be easily adapted to your packaging solutions.

We offer two solutions:

The VELEC Systems team is at your disposal to adapt this technical solution to your needs.

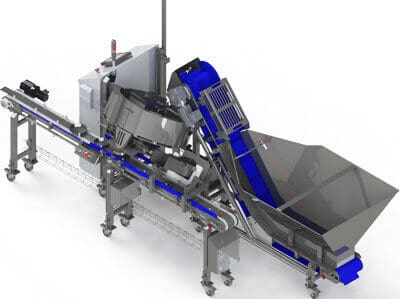

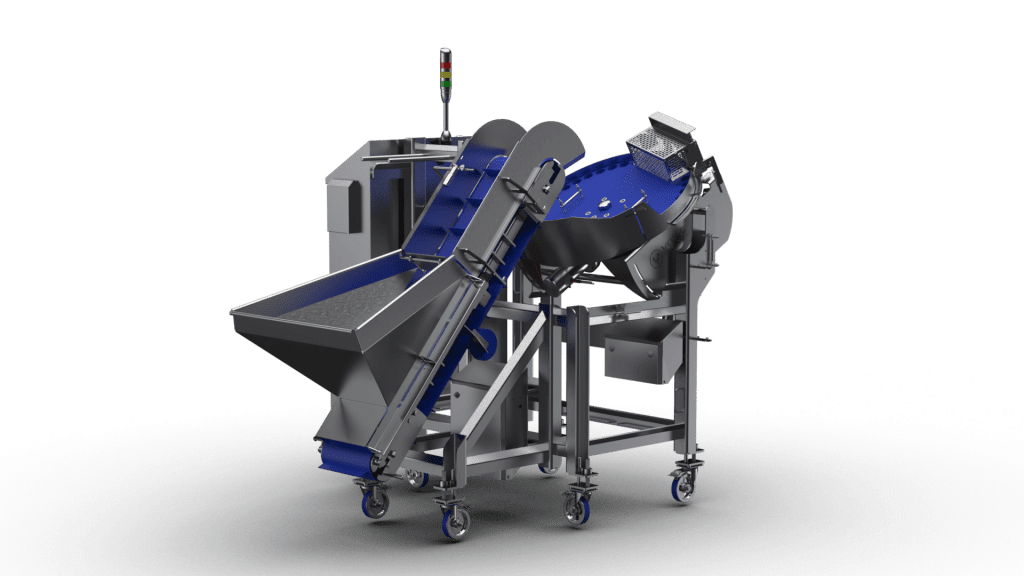

Optimize Your Production Thanks to Compact, High Speed Mechanical Solution

Easy to use, ergonomic and compact, our solution fits into the tightest spaces. It distributes our cutlery in batches, in an orderly, controlled and precise manner. Able to work in unit distribution with products dropped on the fly, or in batches thanks to its dropping hopper, it operates in total autonomy.

- Adaptive it adapts to your cutlery format (size, shape).

- Loads up to 150 cutlery/min.

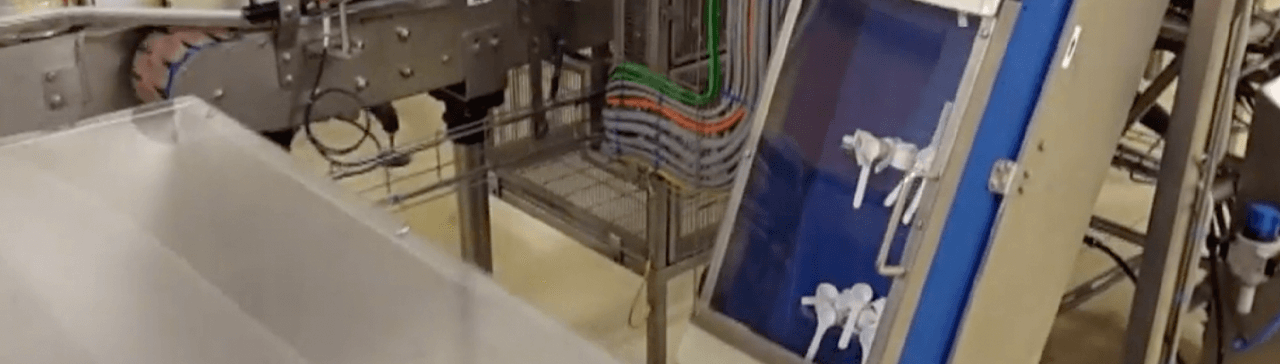

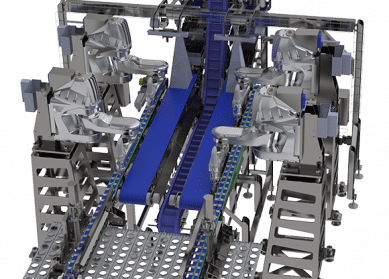

Obtain High Precision and Higher OEE with Our Robotic Solution

Our automatic solution ensures your products are deposited in bulk, in an orderly, controleld and precise manner. Gifted with Scara robots, your cutlery is precisely positioned in the center of your pots. A user-friendly control screen assists you in your operations.

Highly adaptive, it functions with mutliformat cutlery.

- Loads up to 400 meals/min.

- Remote assistance (optional)

Increase your OEE Thanks To the Highest level of Hygiene in your Plant

The food industry’s cold and humid environment is a breeding ground for all kinds of bacteria. Cleaning production lines is a true liability, and it requires perfect monitoring. Our CIP (Cleaning in Place) systems are the perfect solution to help your cleaning team.

HYGIENIC MATERIALS

100% stainless steel and

IP69K (motors, gears, sensors,…) solution

- Hygienic Design+ finish:

Microblasting (ra : 6,4

EASY TO CLEAN

Equipment at human height for easy access, monitoring and sanitation.

- Automation of the cleaning process with our Cleaning-in-Place system

NO WATER RETENTION

Open and incline structure to avoid retention area

- No hollow tubing on all our equipment

saving water and hygiene products

Up to 50% reduction in your water consumption and and disinfection products thanks to CIP.

Possibilty to set up your own cleaning sequence (hot water, foam, sanitizer).